Apex Dynamics will be featuring several new products exhibiting for the first time at PPMA and highlighting others in their servo gearbox range which are particularly relevant for applications in printing , packaging, food processing and similar machines.

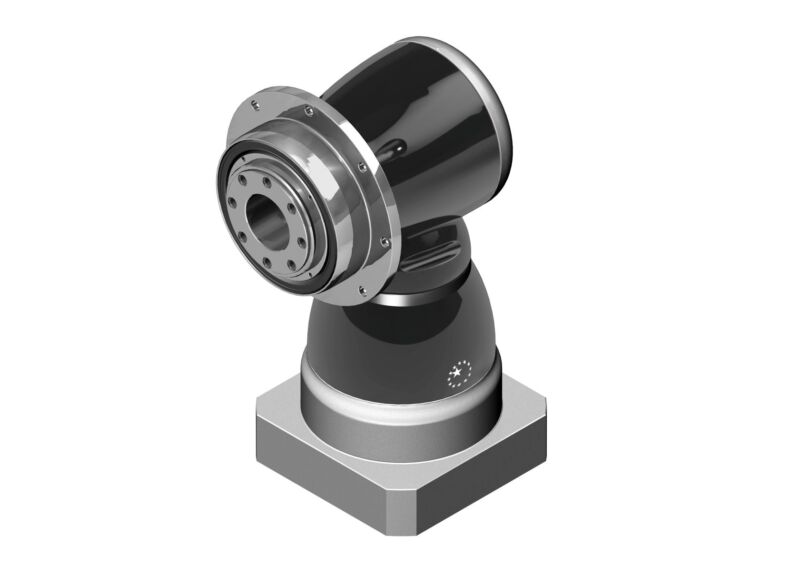

The GL/ GLS series is a high-end servo gearbox range which complements the existing PD/PDR and the PL/PLR ranges and offers a number of technical advantages.

The GL series is designed with high precision helical gears with a maximum backlash of 3 arc minutes for a single stage ratio. With this series, the flange and the housing are made from one rotating part, making it ideal for direct mounting and supporting of the drive wheel without getting high bending moments.

In addition to the GL series, there is also a GLS version with a full input shaft (with or without key), especially for those applications where the wheels or pulley are not direct driven by a motor.

Gearboxes with a planetary transmission have the highest torque density and are therefore compact. They are ideal for mobile robot / AGV warehouse applications widely seen in the PPMA sectors. However, GL/GLS gearboxes are not limited to AGV type applications and there are many other applications that require compact, integrated gearboxes capable of high radial forces, such as belt drives, positioning tables, and other electric vehicles.

Also new is the APEX Dynamics’ fully automatic lubrication system can keep the wheels of production machinery in motion, avoiding unnecessary downtime and expensive early maintenance.

Suitable for any motion system operating in sectors such as medical, packaging, automotive, machine tool, material handling and metal forming, our smart lubrication technology reduces the inherent friction between moving components within a machine.

Suitable for any motion system operating in sectors such as medical, packaging, automotive, machine tool, material handling and metal forming, our smart lubrication technology reduces the inherent friction between moving components within a machine.

Smart technology controls the flow of lubricant according to the particular application need, extending the life of the components it services. Clearly the consequences of insufficient lubrication can be catastrophic. However, over-lubricating not only contaminates the environment, but also wastes lubrication resources, resulting in higher operating costs. Fill monitoring on our system indicates when the reservoir needs to be replenished.

With processing machine operators facing increasing requirements to keep the manufacturing environment clean and contamination free, stainless steel gearboxes are becoming a more viable option for servo applications to enable wash- down procedures without the risk of corrosion or potentially toxic contamination from paint peel.

Apex Dynamics have an ideal solution for precision economical stainless-steel gearboxes with our AES & AERS range. All external gearbox elements are manufactured from stainless steel material, filled with food grade grease and sealed to IP67. Food Grade grease (NYE 670) and durable two-part food grade chip resistant food grade epoxy allow for the planetary gearhead to be mounted above the food line, adding installation flexibility. The shaft and all fasteners are stainless steel, reducing corrosion caused by exposure to cleaning solutions and food by-products.

Launched last year, they are manufactured to the same technical specification as our AE economy helical gearboxes, so you can now have a proven performance in a stainless steel housing making it ideal for food grade applications.

The Hypoid Helical Gearbox KF/KH series will be on show and this range has proved extremely popular for customers with machines in food processing application where important features of the KF/KH series have proved to be:

The Hypoid Helical Gearbox KF/KH series will be on show and this range has proved extremely popular for customers with machines in food processing application where important features of the KF/KH series have proved to be:

- Innovative Hypoid Helical Bevel Gears

- Optimized Inertia Moment High Positioning Accuracy

- High Efficiency, Low Noise and Long Service Life

- Flexible Mounting and Multiple Output Types

- Same Rotating Direction on Output as the Servo-Motor

All Apex Dynamics servo products are offered under our unrivalled package of benefits which support the outstanding performance of our servo products for customers and which includes the following key points of difference:

Patented Designs

5 Year Warranty on all products

2 – 3 Weeks Lead Time

Guaranteed On Time Delivery or the Product is Free to Customer

Largest Range of Planetary Ratios and Drop-In Replacements

ATEX rated as standard

Apex Dynamics Ltd are on stand J42 and welcome visitors to experience our servo control products first hand.

Email: sales@apexdynauk.com

Website: http://www.apexdynauk.com