This month Brady’s Liz Gallagher looks at the traditional holiday month of August, and why it is a perfect chance to review your facility

This month Brady’s Liz Gallagher looks at the traditional holiday month of August, and why it is a perfect chance to review your facility

August can be a frustrating month with so many people away on holiday. It can however also present the perfect opportunity to audit your premises to ensure that once the full workforce is back for the start of the ‘new term’ everyone can power ahead. Here are my top four areas to highlight:

Is your signage clear and compliant?

An inspection tour of your premises should focus on signage. Are all of your emergency escapes clearly signed? Are there any old or faded signs that need replacing? While ISO 7010 is not yet compulsory in the UK, when replacing signage it would be worthwhile ensuring all new products are compliant to save extra expenditure in the future.

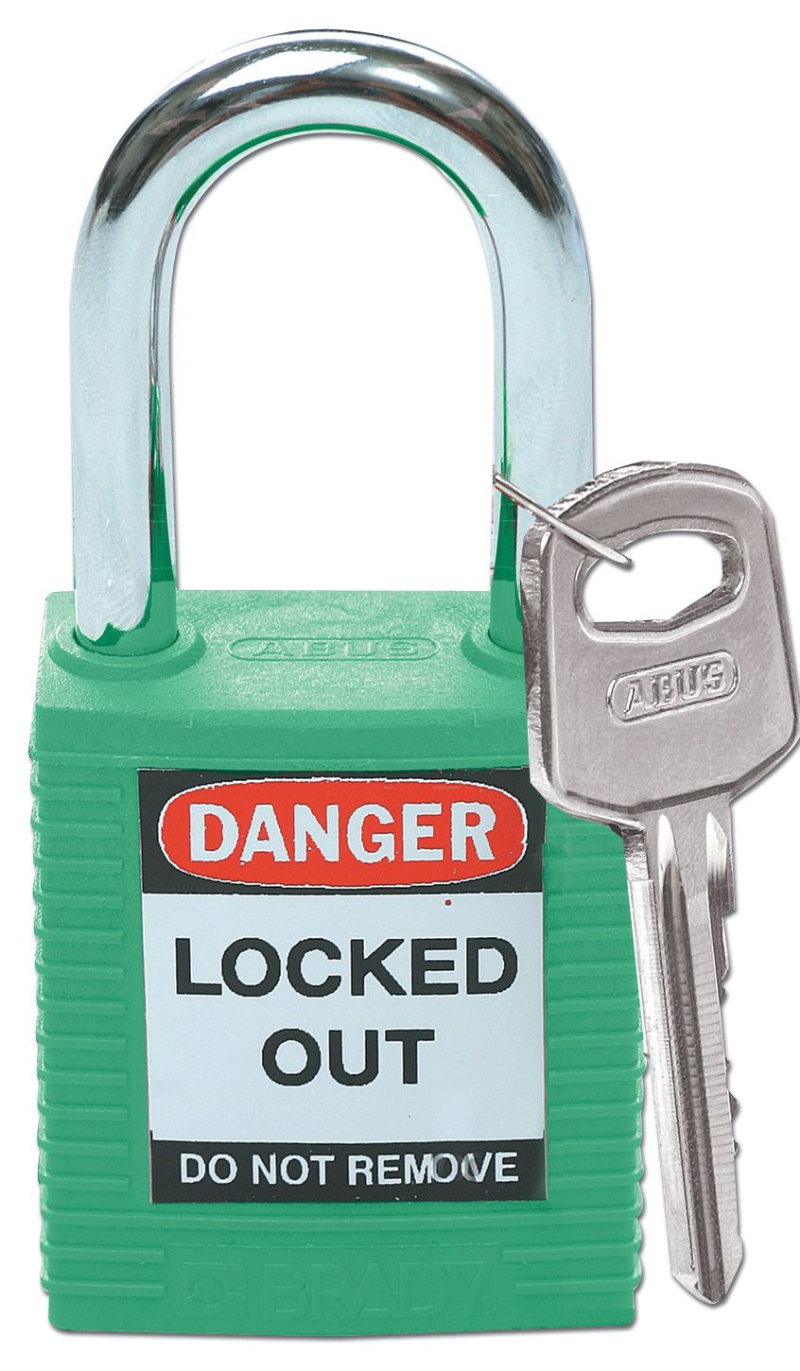

Allocate time for a review of any lockout/tagout programme

Even if you have a slick and well-documented lo/to programme, updates can be necessary for a number of reasons. New equipment or machinery might have been installed, new processes introduced or job functions re-assigned. If the latter, should you introduce extra training for employees?

Even if you have a slick and well-documented lo/to programme, updates can be necessary for a number of reasons. New equipment or machinery might have been installed, new processes introduced or job functions re-assigned. If the latter, should you introduce extra training for employees?

Also, check that all padlocks are uniquely identified and keyed, in full working order and suitable for the equipment and power supply involved. Do you use non-conductive padlocks in electrical areas of the plant for example?

Do the tags used with every lockout device clearly identify the workers designated to maintain and service machinery?

Pipes – are yours clearly identified?

Properly marked pipes minimise delay during an emergency so it is essential to ensure they are clearly marked.

Properly marked pipes minimise delay during an emergency so it is essential to ensure they are clearly marked.

As mundane as it seems, floor marking can contribute to increased efficiency if it is both highly visible and tough. Do you change the layout of your warehouse at all? If so, you should consider using floor marking tape such as ToughStripe which can be easily removed and re-laid

Make sure any pipes carrying hazardous substances are labelled in accordance with CLP/GHS regulations.

Identify pipes that are no longer in service as well as locations where pipes may have changed. Newly installed pipes or locations where temporary piping has been installed are all obvious targets that need correct marking.

Floor Marking – maximise the potential

As mundane as it seems, floor marking can contribute to increased efficiency if it is both highly visible and tough. Do you change the layout of your warehouse at all? If so, you should consider using floor marking tape such as ToughStripe which can be easily removed and re-laid. With the same visibility as freshly-applied paint, ToughStripe can also mark temporary areas as needs dictate.

So there you have it – plenty of food for thought for the holiday month of August. Remember to check out our website for all kinds of safety and identification pointers and materials. It’s all at www.bradyeurope.com.

Brady