This month, Brady’s Expert Liz Gallagher looks at the special challenges posed by extreme environments and the materials that Brady dedicates and develops to deal with such environments

This month, Brady’s Expert Liz Gallagher looks at the special challenges posed by extreme environments and the materials that Brady dedicates and develops to deal with such environments

We have recently won a contract that will expand our production into wiring assemblies for the aerospace industry. For such a specialised environment we are obviously going to review materials used. Will we have to develop our own solution?

While some of our products are developed as a direct result of customer demand we are already well-established in producing materials and labelling specifically developed to cope with the extreme challenges of environments such as aerospace. Brady is one of only a few label suppliers that has full coating facilities meaning we can construct a finished material from scratch. This means taking a polyester, polyimide or vinyl substrate and adding a specific adhesive or top coat to provide the finished properties required for a specific application. Aircraft applications need careful considerations due to the extremes of performance required. In fact, one of my earliest sales successes was to supply one of the world’s largest aeroplane manufacturers with a label that would sit behind the actual jet engine, yet still be legible after thousands of miles of service – that was a very satisfying project to work on!

Flame retardant material

One of our newest products in the aerospace sector is our flame retardant labelling material, B-472. Not a glamorous name, I grant you, but one worth remembering for a number of reasons. Not least of which is adding to our already strong portfolio of flame retardant and aerospace-specific products. B-472 is a matt top coated polyimide wirewrap label material; it is available in industry standard yellow and white and has Federal Aviation Regulation approval in the U.S.A. Its uniqueness stems from its self-extinguishing and flame retardant properties which of course does not restrict its use in the aerospace sector but makes it equally in demand for other mass transit environments and anywhere where wiring is exposed to the potential for combustion. In addition to these fire resistant qualities, the material has been developed to have exceptional resistance to chemicals such as solvents (Skydrol® LD4), oil (MIL-H-5606 Oil), detergents and lubricating fuels. The important thing is that once a material has been created it can then be converted into labels of different sizes that can be printed using thermal transfer printers. Yes we can produce custom made to order sizes, but also make the most popular sizes as finished labels available from stock.

‘It’s not always about extreme environments in the obvious locations – the challenge of developing a label that will adhere to a rusty or oil-coated surface or withstand exposure to the outside elements is essential to meet the daily needs of many factories the globe’

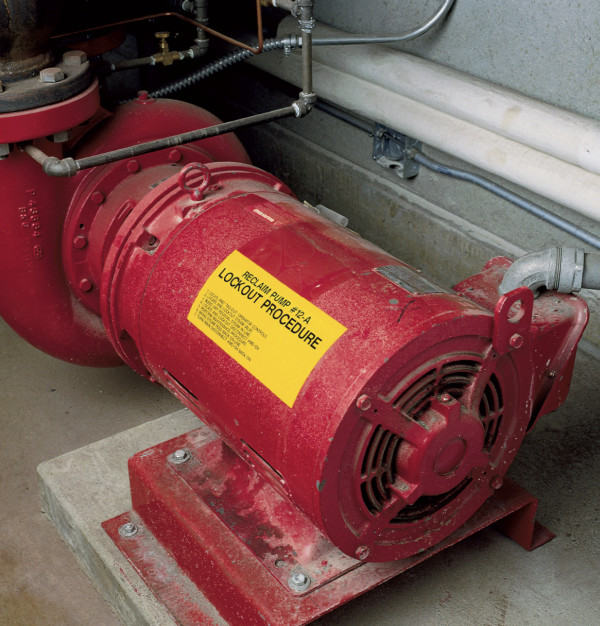

Extreme environments aren’t confined to the obvious locations such as aerospace or oil and gas platforms however. More daily challenges are presented by solving problems such as abrasion, chemical, or UV exposure. The challenge of developing a label that will adhere to a rusty or oil-coated surface or withstand exposure to the outside elements is essential to meet the daily needs of many factories across the globe. If I may just add here, Brady became the first company to achieve 10 year durability for raised panel identification materials, an important addition to our portfolio as it saves our customers both the cost of outsourcing engraved plates and also the need for continual replacement.

Extreme environments aren’t confined to the obvious locations such as aerospace or oil and gas platforms however. More daily challenges are presented by solving problems such as abrasion, chemical, or UV exposure. The challenge of developing a label that will adhere to a rusty or oil-coated surface or withstand exposure to the outside elements is essential to meet the daily needs of many factories across the globe. If I may just add here, Brady became the first company to achieve 10 year durability for raised panel identification materials, an important addition to our portfolio as it saves our customers both the cost of outsourcing engraved plates and also the need for continual replacement.

Withstanding warehouse traffic

On a slightly larger scale, the Brady R&D team has been busy developing our recently launched ToughStripe range that will withstand the heaviest of forklift and other warehouse traffic, remaining visible and untorn under the most testing of traffic volume and as a further bonus, easy to remove and reuse for extra economy.

Do you have a particularly tough identification problem? If so we’d love to hear about it! Please go to www.bradyeurope.com and send us your extreme challenges. We’ll publish the most interesting cases

Brady