The latest addition to Alfa Laval’s spiral heat exchanger range is the stainless steel ALSHE VAP, a standardised exchanger available on fast delivery times and designed for use as a vapouriser in a range of process industries.

The latest addition to Alfa Laval’s spiral heat exchanger range is the stainless steel ALSHE VAP, a standardised exchanger available on fast delivery times and designed for use as a vapouriser in a range of process industries.

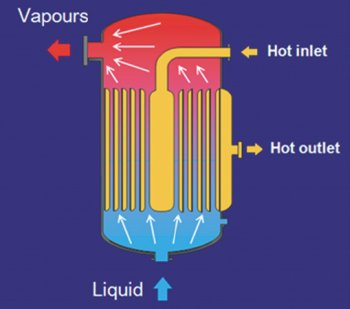

In conventional spiral heat exchangers the media flow is in direct counter-current flow; the ALSHE VAP, however, is configured so that one stream is in spiral flow while the other flows across it, in parallel to its axis.

The spiral flow channel generally accommodates the heating medium, while the cross flow channel is dedicated to the fluid to be vapourised or boiled.

This design ensures that the unit can handle high liquid velocities in the closed, spiral channel and, on the boiling side, the large cross-flow area with a relatively low physical height, makes the unit suitable for operation at low pressure or under vacuum.

The exchanger has a large capacity, yet is compact in size due to its wrapped cylindrical heat transfer surfaces. As a result, capital and installation costs are said to be lower than for an equivalent shell & tube exchanger and the space required for installation and service is reduced by as much as 80%.

There are currently four models in the range, providing the ability to handle temperatures up to 300°C and down to -100°C and design pressures up to 8 bar g.