Telsonic describes how ultrasonic cutting offers advantages in food industry applications, especially where soft and sticky product is concerned. The quick and clean cutting allows quality, yield and output improvements to be made

Telsonic describes how ultrasonic cutting offers advantages in food industry applications, especially where soft and sticky product is concerned. The quick and clean cutting allows quality, yield and output improvements to be made

A historical problem for many food manufacturers has been cutting and portioning a product whilst maintaining the quality, appearance and presentation of the finished item. Although mechanical cutting blades are commonplace within the industry they do have limitations on certain types of product, especially the soft and delicate variants.

The growing use of Ul trasonics however provides not just a practical solution to a diverse range of food cutting operations, but provides significant benefits in terms of quality, yield and output. Ultrasonic cutting uses the high frequency oscillation of the sonotrode (cutting blade) to quickly and cleanly pass through the product being processed.

trasonics however provides not just a practical solution to a diverse range of food cutting operations, but provides significant benefits in terms of quality, yield and output. Ultrasonic cutting uses the high frequency oscillation of the sonotrode (cutting blade) to quickly and cleanly pass through the product being processed.

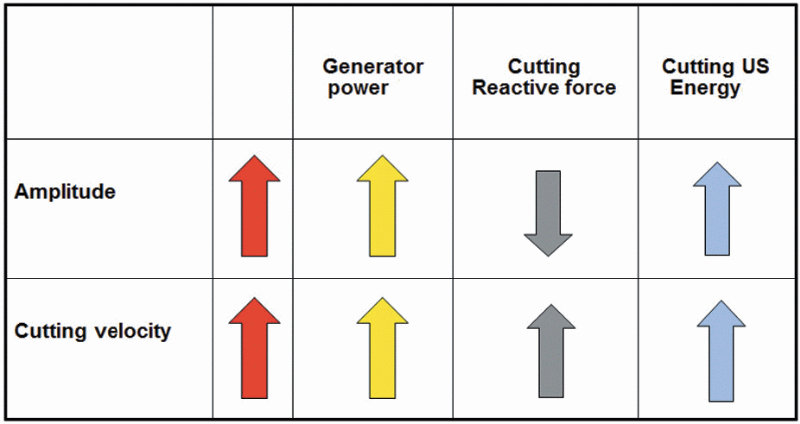

These oscillations can range from 20 to 35Khz depending upon the application and this, combined with defined variations in amplitude, mean that Ultrasonics can be used successfully to process food products ranging from cakes, cheeses, chocolate coated products, pizzas, quiche, pate, meats, bread rolls, sandwiches and snack foods such as flapjacks and cereal bars.

Process and Applied Benefits

The many benefits realised by the application of ultrasonic technology within the food industry include: the ability to cut and slice products, without crumb, crushing or blade contamination problems or down-stream packaging issues experienced with mechanical cutting, and the ease of automating the process in a production environment, offering resultant increases in productivity and quality.

- Vibration energy reduces product reactive force

- High Frequency oscillation reduces adherence of product to the blade

- Thin accurate cuts, reduces crushing and crumbling

- Efficient cut – allows faster cut rate

- Applications – delicate, filled, layered, sticky, non homogenous ie. with nuts, fruit, chocolate or gelatine chunks, fast cut requirement

- Cut quality, cut consistency, yield, throughput

The greatest benefits of ultrasonic cutting can be realised where the technology is applied to soft and sticky produce. The high frequency blade flank surface and tip oscillations and much reduced reactive cutting forces mean that products can be cut and portioned cleanly without the “smearing” or crushing which would normally be associated with conventional mechanical cutting systems.

The greatest benefits of ultrasonic cutting can be realised where the technology is applied to soft and sticky produce. The high frequency blade flank surface and tip oscillations and much reduced reactive cutting forces mean that products can be cut and portioned cleanly without the “smearing” or crushing which would normally be associated with conventional mechanical cutting systems.

With some food products, it may be deemed necessary to clean the ultrasonic sonotrode following prolonged cutting cycles, by submerging the sonotrode in a water bath docking station and initiating an ultrasonic pulse cycle. This simple and quick process can be sequenced to operate automatically as required, maintaining quality and yield and reducing the downtime which would be associated with manual cleaning operations on mechanical cutting blades.

Machine Integration

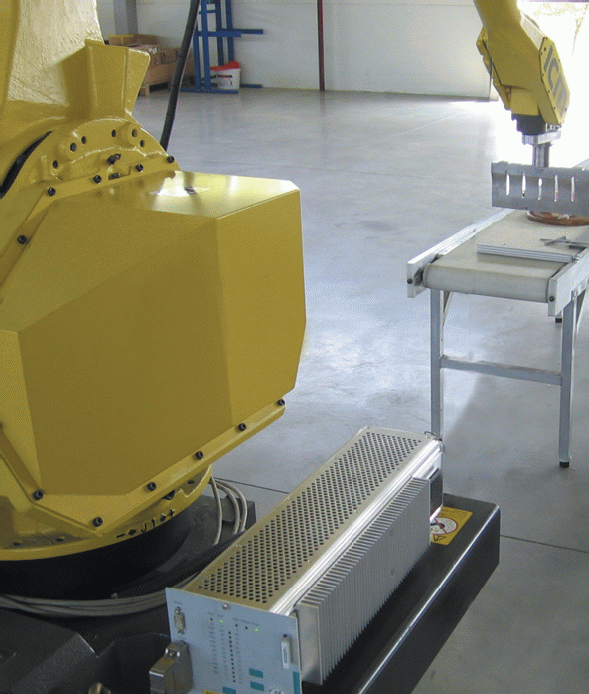

The flexibility of the ultrasonic process allows the technology to be applied in a number of different ways. Typical configurations include “cut and move” where following the vertical cutting process, the sonotrode is then moved horizontally, separating and spacing the slab waste cut portion from the parent product. Ultrasonics can also be easily integrated to robot systems. The multi axes configuration, and large work envelope means that robot mounted ultrasonic cutting systems offer the ultimate in flexibility.

The flexibility of the ultrasonic process allows the technology to be applied in a number of different ways. Typical configurations include “cut and move” where following the vertical cutting process, the sonotrode is then moved horizontally, separating and spacing the slab waste cut portion from the parent product. Ultrasonics can also be easily integrated to robot systems. The multi axes configuration, and large work envelope means that robot mounted ultrasonic cutting systems offer the ultimate in flexibility.

Examples of where ultrasonic cutting technology can be integrated include:-

- In Line Slicers

- Guillotines

- Rotary Portioners

- Robot Installations

For more information please use the contact details below:

Telsonic UK Limited

Units 14 & 15 Birch Copse

Technology Road

Poole

Dorset

BH17 7FH

T: 01202 697 340

E: sales@telsonic.co.uk

www.telsonic.co.uk

Blog – http://telsonicuk.wordpress.com/