Bronkhorst has become firmly established as the market leader in low flow gas & liquid measurement and control by selecting the correct technology and methodology from their broad product repertoire to not only meet any given application, but to exceed expectation. One of the company’s greatest strengths is its competence with Coriolis measurement techniques and, more specifically, its patented Mini-Cori flow sensor. By using this core technology, together with their knowledge and experience, Bronkhorst have assisted many of their customers by increasing their product quality whilst reducing costs and optimizing process improvement. An example of such improvement can be seen below.

Bronkhorst has become firmly established as the market leader in low flow gas & liquid measurement and control by selecting the correct technology and methodology from their broad product repertoire to not only meet any given application, but to exceed expectation. One of the company’s greatest strengths is its competence with Coriolis measurement techniques and, more specifically, its patented Mini-Cori flow sensor. By using this core technology, together with their knowledge and experience, Bronkhorst have assisted many of their customers by increasing their product quality whilst reducing costs and optimizing process improvement. An example of such improvement can be seen below.

Existing application and process : A customer within the field of specialist chemicals was unaware that low to ultra-low flow control was possible and so was taking a vital raw ingredient, mixing it with water to create a carrier volume, and then metering and dosing it into the main product flow. This process added cost to the production method and, as the dilution step added variability to the concentration of the additive, product quality was often compromised with a resulting additional cost of re-work to the rejected product. Furthermore, the final process step saw the bulk material being heated and stirred to evaporate the added water to reduce volume and increase concentration. The energy requirement to do so was significant and the operational stock-holding was high. Further complications were added by the need for the “dosing system” to handle multiple additive doses with stringent cleaning needed between batches resulting in yet more wastage and high additional cost.

Bronkhorst solution : following several months of close co-operation and collaboration the joint team were able to establish that the concentrated raw ingredient should be added via a highly accurate low flow Coriolis Flow Meter directly coupled and controlling a precision pump. This solution ensured that the costly addition and removal of the water could be eliminated and that very close tolerances on the dosage rate, and hence final product quality, could be maintained. The inclusion of multiple synchronous injection points eliminated the costly clean-down process and the reduction of working process volume also reduced the stock holding inventory further reducing operational costs. Re-producable product quality has been increased, productivity has been increased, wastage has been reduced, energy consumption has been reduced and operational costs dramatically reduced .

Bronkhorst solution : following several months of close co-operation and collaboration the joint team were able to establish that the concentrated raw ingredient should be added via a highly accurate low flow Coriolis Flow Meter directly coupled and controlling a precision pump. This solution ensured that the costly addition and removal of the water could be eliminated and that very close tolerances on the dosage rate, and hence final product quality, could be maintained. The inclusion of multiple synchronous injection points eliminated the costly clean-down process and the reduction of working process volume also reduced the stock holding inventory further reducing operational costs. Re-producable product quality has been increased, productivity has been increased, wastage has been reduced, energy consumption has been reduced and operational costs dramatically reduced .

Although currently configured for control via the client DCS the Bronkhorst Coriolis Meter can, if needed, be “paired” with the main process line flow meter to act in master/slave mode. Standard on-board firmware can be utilized to immediately match the required dosage rate to any variability within the main flow line. This facility eliminates any time lag in process response and further enhances the very tight tolerances on product quality.

A host of secondary benefits have also been utilized within the solution. The density of the concentrated natural raw ingredient is measured, recorded and trended thereby allowing tracking of the natural innate variability and further fine-tuning the control process. The pump steering signal is utilized for condition monitoring and as a preventative maintenance tool. This, together with dry-running protection, will ensure less emergency break-down and catastrophic down-time.

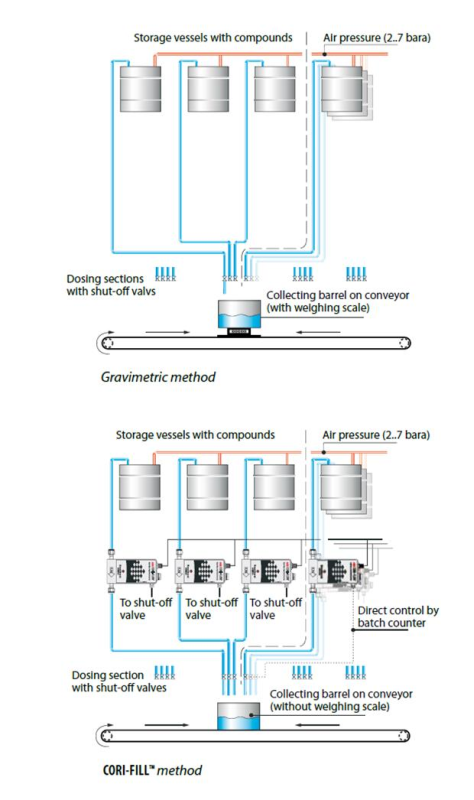

Technical specification : accuracy of +/-0.2% Reading, the instrument is certified to ATEX Zones 1 and 2, on-board PID control is standard, as is over-run protection and a self-learning function, the turn-down ratio is 2000:1, flow rates down to 0.1 grams per hour have been easily achieved and the physical size (“the smallest Coriolis instrument in the world”) has proven to be perfect for multiple injection points within a confined space. This particular customer preferred gear pumps but the Coriolis system can be integrated with virtually any pump technology, control valves or indeed shut-off valves should the application demand it.

For more information on the Mini Coriolis instrument please contact us; Bronkhorst UK Ltd, Email: sales@bronkhorst.co.uk, T: 01223 833222