Rob Richards from pump hire specialist, Sykes Pumps, discusses the business critical temporary pump solution at Anglian Water’s Water Recycling Centre in Caister, Norfolk, designed to manage return activated sludge levels during infrastructure maintenance.

Rob Richards from pump hire specialist, Sykes Pumps, discusses the business critical temporary pump solution at Anglian Water’s Water Recycling Centre in Caister, Norfolk, designed to manage return activated sludge levels during infrastructure maintenance.

The waste water treatment processes at Anglian Water’s Caister Water Recycling Centre in Norfolk rely on careful management of the return activated sludge (RAS) in the final settlement tanks.

Rich in enzymes that help to clean the water and remove unwanted bacteria, the RAS is critical to both the first and final elements in the waste water treatment process.

A sludge blanket needs to be managed at the correct levels in the final settlement tanks to maintain and improve the water quality before it is released into the water courses. The RAS content required in the final settlement tanks varies depending on throughput of waste water at the facility.

Meanwhile, the RAS that is not required in the final settlement tanks is returned to the primary processing tanks at the head of works as an essential component in beginning the processing cycle.

Too much RAS in the final settlement tanks or too little in the initial processing could have a critical impact across the whole water recycling centre. When routine maintenance was required to the adjustable bellmouths used to control the amount of RAS taken from the final settlement tanks and returned to the head of works, Anglian Water needed a temporary over pumping solution that would enable the bellmouths to be taken off line, while ensuring that the correct levels of sludge were returned to the head of works and maintained in the final settlement tanks.

As a category A supplier to Anglian Water, IOS (Integrated operational solutions) developed a suitable solution and, following a site visit to fully assess the requirements, six of our duty pumps were specified for the over pumping requirements, with an additional three pumps provided to site as standby units.

Over Pumping Connection

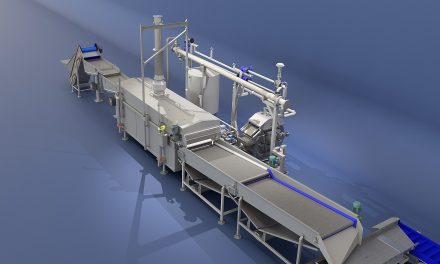

Sykes Pumps deployed six Super Wispaset 200 8” diesel pumps, each with a flow rate of up to 580m3 per hour, for each of the final settlement tanks 1-4. An additional two Super Wispaset 200 pumps were installed for standby use. For tanks 5-6 where the required flow rate was lower, a 6” Super Wispaset 150 pump was specified for each tank, with a further 6” pump installed as standby.

The pumps were supplied to site with four fuel tanks, 174m of 8” wire armour hose, 84m of 6” wire hose, 84m of 8” polyurethane piping and 42m of 6” polyurethane piping. This enabled Anglian Water IOS to connect the pumps to the existing pipework so that sludge could be pumped directly into the network for transferring RAS from the final settlement tanks back to the head of works, while bypassing the chambers where the bellmouths are located during the repair works.

The fuel tanks ensured that the pumps could run constantly over the course of the over pumping operation without risk of interruption, while daily site visits from Sykes Pumps technical team ensured that the pumps were checked and in excellent working order at all times.

Managing the Flow

As the bellmouths are usually used to control the flow of the RAS from the final settlement tanks, management of the flow rates had to be built into the over pumping installation. Anglian Water’s engineers fitted control valves into the pipe gallery below ground and these were manually connected to a temporary piping manifold and operated via an iOS control system.

Anglian Water’s IOS site team was then able to adjust the flow by monitoring sludge blanket levels using telemetry technology installed on all the pumps as part of the pump hire specification. This allowed 24/7 remote monitoring of flow rates so that these could be adjusted in real time if the sludge blanket needed to be increased or reduced.

Due Diligence

Although the pumps were on hire for two weeks, the over pumping operation itself was required for just three days while the RAS lanes were out of commission.

Although the pumps were on hire for two weeks, the over pumping operation itself was required for just three days while the RAS lanes were out of commission.

The over pumping was so process critical, however, that significant due diligence was involved in the specification and installation stages, with a week invested in installing, commissioning and testing the over pumping capability before management of the RAS was transferred to the temporary set up. Decommissioning was a similarly meticulous process, carried out over the course of a week following the reinstatement of the bellmouths.

The project was successfully completed in February with zero risk of process interruption throughout.

info@andrews-sykes.com

0800 211 611

www.sykes-pumps.com