With companies such as Just Eat making national headlines with commitments to raising hygiene and safety standards and EU data showing ‘significant increases’ in product alerts over recent years, there is no time for complacency when it comes to food safety. A recent SKF white paper has even shown that some standard maintenance and cleaning procedures are actually helping contaminants travel and thrive. However, these issues can be quickly and easily resolved with the use of hygienically designed bearing components.

With companies such as Just Eat making national headlines with commitments to raising hygiene and safety standards and EU data showing ‘significant increases’ in product alerts over recent years, there is no time for complacency when it comes to food safety. A recent SKF white paper has even shown that some standard maintenance and cleaning procedures are actually helping contaminants travel and thrive. However, these issues can be quickly and easily resolved with the use of hygienically designed bearing components.

Bacteria growth in bearing units

When it comes to the food zone, manufacturers employ strict cleaning processes to ensure the safety of their products. However, mounted bearings present an often unaccounted for risk, as they are magnets for bacteria. In fact bacteria can even enter bearings and spread as the result of the cleaning washdown process.

This is because bearings rely on suitable lubrication for longevity and reliability, but the grease in these units attracts contaminants. High pressure washdowns can exacerbate the problem, forcing water, cleaning fluids and particles past seals and into the interior of the component. Traditional relubrication methods, wash-downs and the dry cleaning of these bearings can subsequently transfer contaminants from the unit to other hygienic surfaces. Once contaminants are in the food zone, they can then put food products—and consumer health—at risk.

Even purchasing stainless steel machines labelled “food grade” or installing workarounds, such as spacer- mounted bearing units, doesn’t necessarily mean safe or clean operations. To truly align food-safety and production efforts, organisations need to examine how every action around the food zone impacts their goals—and extend hygienic-design thinking to every component involved in the process.

How can this issue be resolved?

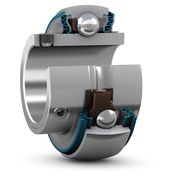

One of the first steps to achieving safe, clean processing operations is by replacing bacteria and allergen traps in the food zone with completely sealed and hygienically designed bearing units that promote self-draining and deter soiling, regardless of mounting orientation.

Relubrication-free technology should be chosen, that prevents grease leakage to food zones during hygienic cleanings. As well as food-grade components being used throughout – from the material of the housing to the bearing seals – the bearing grease selected should be allergen-free and food-industry certified.

Production uptime and relubrication

Production uptime and relubrication

No food producer wants unplanned downtime and much of this stems from ineffective bearing lubrication. For example, what happens when workers miss lubrication points through simple human error, or the pipes within automatic lubrication systems become clogged? These can lead to failures that grind production to a halt, negatively impacting output — and thus the bottom line.

To eliminate relubrication issues and to improve asset reliability, food producers have come to rely on a range of lubrication strategies designed to maximise the life and performance of the rotating component. However, frequent relubrication is not only time intensive, but it has additional cost implications in terms of the cost of the grease and the consumables required for cleaning afterwards. This is why many food producers are now seeing the benefits of relubrication-free technologies such as the latest one launched by SKF in January.

Hygienic-design from SKF saves time and money

The new SKF Food Line ball bearing units – Blue Range have been specifically designed and engineered from the ground-up, to uniquely address food safety, uptime, cost efficiency, and sustainability issues. These new, relubrication-free, corrosion resistant bearings have hygienically designed housings for improved cleanability and contain 100% food-grade components. A completely sealed option is also available if needed. The Food Line range has also been designed with a patent-pending sealing system that works with the cleaning media (as opposed to completely excluding it), to prevent ingress and damage.

The SKF Food Line bearing unit range incorporates a host of innovations that address many of the long-standing issues associated with conventional bearing units:

- An over-moulded rubber base seal in the housing that prevents contamination and bacteria growth between the unit and the mounting frame

- A special back seal and end cover to prevent process material from entering the bearing from either side

- A patented locking mechanism on the end cover, to ensure it cannot be accidentally dislodged

- Angled surfaces and a smooth surface finish to reduce material accumulation and ensure liquids drain away easily, regardless of bearing orientation

- A special multi-lipped sealing arrangement (another patented innovation) to keep lubricant inside the bearing and contaminants out

- Factory-installed lubricant that is designed to last for the full life of the bearing unit, eliminating the need for regular relubrication and all the associated costs and risks.

Thanks to the SKF Food Line ball bearing unit range, food producers are now able to extend hygienic-design thinking to every component within their food-processing operations, helping them achieve their most critical food safety goals, whilst contributing to increased asset availability and cost reductions.

To learn more about SKF Food Line products:

http://industry.promo.skf.com/acton/media/26642/food-safe-bearings