At Silverson Machines we’ve released a new video detailing how our Silverson Ultramix in-tank mixer works and we’d like to take this opportunity to tell you more about the mixer and how it could potentially help to improve your process or application.

At Silverson Machines we’ve released a new video detailing how our Silverson Ultramix in-tank mixer works and we’d like to take this opportunity to tell you more about the mixer and how it could potentially help to improve your process or application.

What is the Ultramix?

The Silverson Ultramix was developed for applications which are beyond the capabilities of conventional mixing equipment such as agitators and stirrers, but do not necessarily require the intense high shear of a rotor/stator mixer. For example, applications which require the rapid wetting out powders including gums and thickeners, or the preparation of Brines for the meat industry.

It is also suitable for applications which use shear-sensitive ingredients that can deteriorate if too much shear is implied during the production process, but without sacrificing the benefits associated with high shear mixing equipment.

The Ultramix comprises of a dynamic mixing head which is able to achieve excellent in-tank movement, making the mixer ideal for mixing in difficult shaped containers. The vigorous mixing action produced by the mixing head is able to circulate the entire contents of the vessel, even at high viscosities, so localised mixing is minimised/eliminated.

How is it different from other Silverson mixers?

How is it different from other Silverson mixers?

Unlike many of the other products in the Silverson mixing range, the Ultramix does not have a rotor/stator workhead, instead the Ultramix has a single-piece dynamic mixing head. It’s a simple, robust design with no wearing parts or bushes making it Ultra-Hygienic in design and suitable for applications from aggressive chemical service to the most demanding sanitary standards and requirements.

Because of the small diameter of the workhead, the Ultramix can provide effective mixing even in vessels with narrow openings. For this reason the Ultramix is ideal for mixing in problematic containers and offers considerable advantages for customers using IBCs and Tote Bins. The highly efficient in-tank movement provided by the workhead overcomes the problems often encountered with difficult vessel geometry.

The Ultramix also offers an advantages in that it has a reduced power requirement compared with conventional high shear mixers, making it more economical.

How does it work?

How does it work?

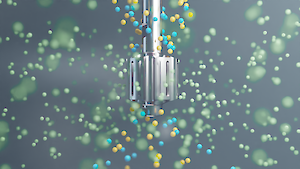

Our latest video explains using animation exactly how the Ultramix is able to create a powerful vortex which can rapidly incorporate large volumes of powder and continually move the entire content of the mixing vessel.

As the mixer rotates at high speed, the grooves on the outside of the dynamic mixing head project the surrounding product outwards with great force, creating an area of low pressure inside the head which draws materials from the top and bottom of the vessel into the head.

Centrifugal force then projects the materials outwards, subjecting them to a shearing action as they pass through the radial slots in the head and are projected back into the vessel at high velocity. Fresh material is simultaneously sucked in through the holes in the top and bottom of the mixing head.

The pumping effect of the grooves and the shear action of the radial slots ensures rapid mixing, and develops a vigorous flow pattern throughout the vessel which keeps the contents moving and rapidly incorporates ingredients.

Mixer options

The Silverson Ultramix can be used on batches of varying sizes from Laboratory scale, up to full scale production. The Silverson L5 Series Laboratory mixer can be used with an Ultramix laboratory mixing assembly, allowing the user to replicate the mixing characteristics of the production scale Ultramix units in the laboratory in batches of up to 12 litres, depending on product viscosity. The laboratory mixing assembly is ideal for applications with a smaller batch sizes or for research and development as results can easily be scaled up to a larger Ultramix model if required.

While they are primarily designed for vessel mounting, some production scale Ultramix mixers can be supplied on stands so they can easily be moved from vessel to vessel on the production floor and easily lowered into IBCS and Tote Bins. The Ultramix can also be supplied as a Bottom Entry unit, ideal for ultra-hygienic applications in the pharmaceutical and food industries.

The Ultramix – how it works video is available to view on the Silverson YouTube channel. You can find out more about the Ultramix on the Silverson website, or if you’d like to discuss your mixing application with us, please contact us today.

Company details:

Company details:

Silverson Machines Ltd.

Address: Waterside, Chesham, Buckinghamshire, HP5 1PQ

Phone: +44 (0)1494 786331

Email: sales@silverson.co.uk

Website: www.silverson.com

YouTube: https://www.youtube.com/user/silversonmixers

LinkedIn:https://www.linkedin.com/company/silverson-machines-inc-/

Twitter: https://twitter.com/silversonmixers

Facebook: https://www.facebook.com/silversonmixers