Silverson Machines have just released an updated product video on their YouTube channel and website on the largest mixer in their product range which has a capacity from 1,000 to 100,000 litres – the Disintegrator 2500.

Silverson’s mighty Disintegrator 2500 mixing system, or D2500, is designed to disintegrate, solubilise or disperse the largest of solids in a single operation. There is no need for pre-grinding, slicing or cutting of large solids before they are added into the mixing vessel, eliminating the need for additional equipment such as grinders or guillotines which significantly reduces maintenance cost and dust emissions. Processing times can be cut from 24 hours or more to just a single shift.

The D2500 can take odd shapes, whole bales of rubbers and up to the largest size polymer bales commercially produced, including poly-wrapped bales, without the need for preliminary chopping or crumbing. This unique system is used by many of the world’s major oil companies for the production of viscosity index improvers for lube oils; it is equally effective on solid or cold-flow type polymers and new generation compressed powder bales. It is also used in applications as diverse as the dispersion of filter cake, wet crumbing of waste rubber, recovery/reclaim of waste confectionery and manufacture of adhesives.

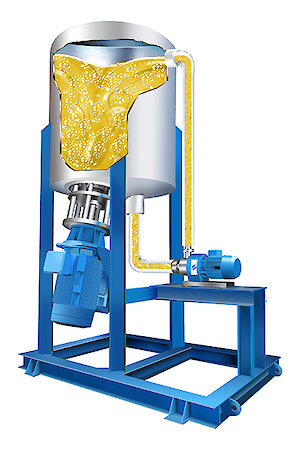

The D2500 is a powerful self-contained system comprising of two Silverson high shear mixers; a specially designed disintegrating workhead which is located in the bottom of the custom-built vessel, and a high shear In-Line mixer. These work in conjunction with one another and enable the D2500 to disintegrate large solids and fully disperse and solubilise them in a fraction of the time taken by conventional systems. The Bottom Entry mixer provides the initial disintegration of solids, while the In-Line mixer refines the solids until they are completely homogeneous, solubilised or suspended. This makes the D2500 ideal for other applications such as the rapid dispersion of large volumes of powder or materials which are difficult to wet out and have a tendency to “raft” on the surface of the mixing vessel.

The D2500 is a powerful self-contained system comprising of two Silverson high shear mixers; a specially designed disintegrating workhead which is located in the bottom of the custom-built vessel, and a high shear In-Line mixer. These work in conjunction with one another and enable the D2500 to disintegrate large solids and fully disperse and solubilise them in a fraction of the time taken by conventional systems. The Bottom Entry mixer provides the initial disintegration of solids, while the In-Line mixer refines the solids until they are completely homogeneous, solubilised or suspended. This makes the D2500 ideal for other applications such as the rapid dispersion of large volumes of powder or materials which are difficult to wet out and have a tendency to “raft” on the surface of the mixing vessel.

A typical mixing process using the D2500 is as follows: The unit is charged with liquid and the bottom entry mixer is started. It exerts a massive suction downwards from the surface of the liquid, pulling down even the most buoyant of solids, no matter what the size. Large solids are fed into the vessel and drawn down to the workhead which will rapidly shear lumps and slices off the edges and corners. Rapid fragmentation of the large solids continues until all the particles are small enough to be drawn into the workhead for further disintegration. The materials are subjected to intense high shear in the gap between the rotor tips and the inner wall of the stator as they are forced out through the slots in the stator, expelled radially from the workhead and projected against the vessel walls before being drawn back down into the high shear zone. This cycle continues until all solids are reduced to granular size, whilst the workhead maintains movement of the fluid in the vessel, even as viscosity rises.

Once the solids are reduced to granular size the self-pumping In-Line mixer is started. The product is drawn from the bottom of the vessel, processed through the In-Line mixer’s high shear rotor/stator workhead and passed back into the top of the vessel. The solids are progressively reduced in size with each pass through the workhead. This accelerates the solubilisation process to complete the operation.

For smaller batch sizes of up to 250 litres Silverson offers a small scale version of the D2500, the Pilot Disintegrator Plant. This self-contained system has wide applications in the food and chemical industries and can be custom-built to meet customers specific requirements.

For smaller solids, Silverson offers the Duplex Disintegrator/Dissolver, which was specifically developed for the disintegration and solubilisation of solid rubbers and polymers for the lube oil and adhesive industries.

To find out more about the D2500 you can watch the latest Silverson product video on the Silverson Machine YouTube channel or visit the Silverson website.

To discuss your application, please contact us at sales@silverson.co.uk