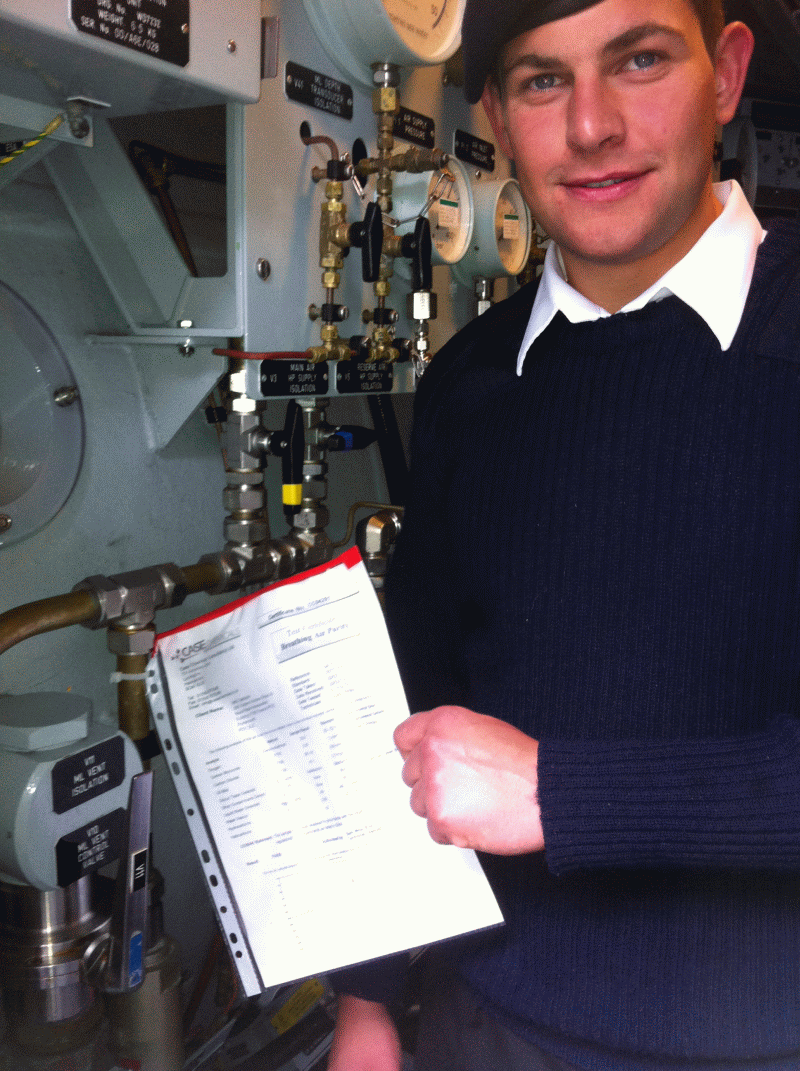

An advanced multiparameter gas analysis technology (FTIR) from Quantitech is being employed by Case Chemicals to analyse diving gas for recreational, commercial and military divers. According to Case’s Sam Wray, “This technology provides much higher levels of confidence than traditional techniques, partly because it is highly accurate and also because FTIR can detect almost any gas or vapour.”

An advanced multiparameter gas analysis technology (FTIR) from Quantitech is being employed by Case Chemicals to analyse diving gas for recreational, commercial and military divers. According to Case’s Sam Wray, “This technology provides much higher levels of confidence than traditional techniques, partly because it is highly accurate and also because FTIR can detect almost any gas or vapour.”

Background

In addition to the supply of chemicals, Case also provides analytical services for a wide variety of applications including occupational exposure, legionella, asbestos, contaminated land, waste acceptance, industrial emissions and breathing gases.

In addition to the supply of chemicals, Case also provides analytical services for a wide variety of applications including occupational exposure, legionella, asbestos, contaminated land, waste acceptance, industrial emissions and breathing gases.

The quality of diving gas is protected by routine analysis of sample bottles taken from the compressors that generate compressed air. The Health & Safety Executive (HSE) requires samples of air supplied for breathing apparatus to be tested at least once every three months and more frequent tests would be necessary if contamination is foreseeable within this three month period.

The standard BS EN 12021 requires that all contaminants should be kept to as low a level as possible and shall be not greater than 10% of the UK 8hour time weighted average exposure limits which are specified in the HSE publication EH40.

FTIR multiparameter analysis

The FTIR analyser employed by Case Chemicals was supplied by Quantitech’s Dr Andrew Hobson who pre-configured the analyser (a Gasmet DX4030) to measure a wide range of parameters including CO, CO2, hydrocarbons, NH3, HCl, HF, NO2, N2O, SO2 and a range of halocarbons such as Freon. This configuration was established to meet and exceed the requirements of both BS EN 12021 and the military standard DEF STAN 68-284.

The FTIR analyser employed by Case Chemicals was supplied by Quantitech’s Dr Andrew Hobson who pre-configured the analyser (a Gasmet DX4030) to measure a wide range of parameters including CO, CO2, hydrocarbons, NH3, HCl, HF, NO2, N2O, SO2 and a range of halocarbons such as Freon. This configuration was established to meet and exceed the requirements of both BS EN 12021 and the military standard DEF STAN 68-284.

Commenting on the benefits of FTIR, Sam Wray says, “In the past, some of our clients have used chemical stain tubes which can have an error of up to 30%, so whilst these are individually cheap, they are highly inaccurate in comparison with FTIR. The tubes also only test for an individual parameter, so they are incapable of detecting any contamination other than the parameter on test.”

Highlighting the importance of being able to detect a very wide range of chemicals, Sam refers to a sample of gas that was supplied by a leisure diving company in the Middle East. “FTIR analysis revealed an unacceptable level of formaldehyde which was traced to a cleaner that was being used on-board the ship – without this analytical technique it is unlikely that the formaldehyde would ever have been detected,” he says.

Highlighting the importance of being able to detect a very wide range of chemicals, Sam refers to a sample of gas that was supplied by a leisure diving company in the Middle East. “FTIR analysis revealed an unacceptable level of formaldehyde which was traced to a cleaner that was being used on-board the ship – without this analytical technique it is unlikely that the formaldehyde would ever have been detected,” he says.

Although the DX4030 is a portable FTIR analyser, Case Chemicals have it permanently located in one of their laboratories and Sam says “It has been extremely simple to operate; calibration is merely a quick zero check in the morning. We are therefore looking to exploit the flexibility of FTIR in other markets – for example, we are planning to offer FTIR analysis for other forms of compressed air, occupational health investigations, contaminated land and even anaesthetic gases.”

Quantitech Ltd

Unit 3

Old Wolverton Road

Milton Keynes

MK12 5NP

t. 01908 227722

f. 01908 227733

Email quant@quantitech.co.uk

Website: www.quantitech.co.uk