Fabcon Food Systems, one of Europe’s leading food processing equipment manufacturers, has strengthened its engineering team with the appointment of a respected project manager.

Engineering projects expert Michael Pye has joined Fabcon’s 24-strong team – taking on the management and delivery of a variety of projects in the company’s UK, European, African and Middle Eastern markets.

A specialist in the development and installation of the company’s snack production systems, 52-year-old Michael will work closely with third-party contractors, equipment suppliers and designers – also supporting customers with production scheduling and capacity planning.

Michael’s arrival at Fabcon coincides with an upsurge in the company’s order book and a notable acceleration in the breadth and complexity of the nature of their world-wide contracts – partnerships which demand ever-increasing scheduling as well as watertight internal and external coordination.

Michael’s arrival at Fabcon coincides with an upsurge in the company’s order book and a notable acceleration in the breadth and complexity of the nature of their world-wide contracts – partnerships which demand ever-increasing scheduling as well as watertight internal and external coordination.

Trevor Howard, managing director of Fabcon Food Systems, said: “To have someone with Michael’s credentials here at Fabcon is tremendous for us and he will play an important role in our expansion.

“His knowledge and experience is already benefiting our customers as we work with them to design and install a variety of new systems and machinery which meet their needs.

“Michael is a perfect fit for Fabcon. His reputation is second to none and he is exactly the type of person we want as part of our leadership and technical teams.”

Michael added: “Fabcon is firmly establishing itself as an innovative manufacturer and supplier of production machinery to the food industry. I am delighted to be part of the team and to have the opportunity to play a role in the company’s ongoing success.

Michael added: “Fabcon is firmly establishing itself as an innovative manufacturer and supplier of production machinery to the food industry. I am delighted to be part of the team and to have the opportunity to play a role in the company’s ongoing success.

“With clients across the world it is a really exciting time for me, especially to be working with such a wide variety of customers both in Europe and further afield.”

2017 has seen Fabcon executing several major contracts, including a major installation at Essex-based Fairfields Farm Crisps which included frying, distribution and seasoning equipment.

Yet another high-profile contract in the past 12 months was a prestigious Fabcon installation for a newly-built factory in Kuwait for the respected Hectare’s brand – part of the AlWazzan Foodstuff Industries Group. The Middle East deal saw Fabcon supply potato chip batch fryers alongside pre-process equipment, optical sorting, distribution and seasoning equipment.

Fabcon’s success story has not stopped in either Essex or Kuwait and several further major orders have been secured with details to be released in the coming months.

Fabcon’s success story has not stopped in either Essex or Kuwait and several further major orders have been secured with details to be released in the coming months.

Aside from new orders and contract wins, the Fabcon team has concentrated on maintaining its profile and showcasing its expertise.

For the first time, the company exhibited this year at Vienna’s popular Snackex show, the main European snack industry exhibition, which again attracted global visitors. Interest from new contacts made at the prestigious show has already led to a variety of new orders for Fabcon, including one from Australia.

A second opportunity to shout about its growing reputation saw Fabcon taking a stand at the Gulfood Manufacturing show in Dubai. The company’s presence in the UAE again awoke considerable interest with many follow ups already taking place as Fabcon cements its growing reputation as an innovative and trusted industry supplier and partner.

About Fabcon Food Systems

Formed in 2015, Fabcon Food Systems manufacture, supply and install handling and processing equipment for the food industry. Designed and built at the company’s Norwich factory, Fabcon supply their systems and machinery to customers in the UK, mainland Europe, the Middle East, Australia and Africa.

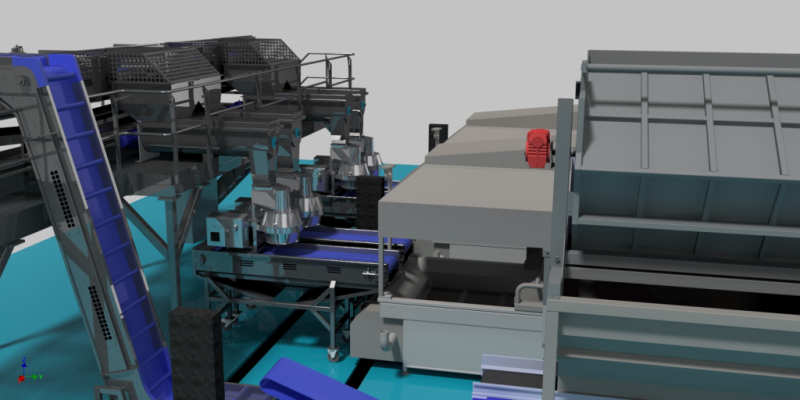

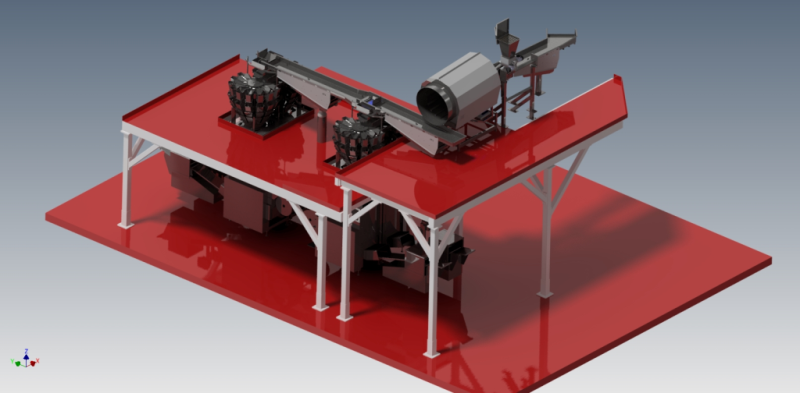

Fabcon’s expertise is all about providing complete systems for a wide range of products from initial concept to final execution – giving its customers the best possible food handling solutions for processing, product handling, sorting, precision flavouring, weighing and packing.

Its products focus on a complete solution for customers – everything from energy savings to ease of cleaning and accessibility.

Fabcon’s areas of expertise include:

- Potato chip (crisp), French fry and pellet frying and associated equipment (peeling, washing and de-stoning)

- Distribution and high precision seasoning of potato chips (crisps), tortilla chips and many other snack products

- Handling of fresh, chilled or frozen food products, eg confectionery, meat/poultry/seafood, potato products, vegetables and pet foods, including conveying, screening, grading

Fabcon’s official website is available through www.fabcon.co.uk. For further information, readers can email info@fabcon.co.uk or telephone +44 (0)1603 482338.