GM Flow Measurement Services Ltd were formed in 2014. The founder has over 35 years of flow measurement experience, gained with some of industry’s largest names. GM Flow are a niche flow measurement company, focusing on specific areas which customers tell us are hard to measure – high pressure gas and liquids are our speciality, we regularly measure fluids at up to 689 Bar (10,000 PSI). Our most recently developed product is for high pressure hydrogen for vehicle fuelling applications where we can measure hydrogen gas at up to 1034 Bar (15,000 PSI).

Adjusta-Cone for High Flow Range Applications

Our initial core business is measuring natural gas during oil and gas well testing operations. Each well is tested regularly to measure the output of oil, water and gas and the equipment used has to have a very wide flow range to be used on every type of well. Adjusta-Cone® was developed to replace dual chamber orifice meters which require a large installation space, are costly and hazardous to use and maintain and which are prone to damage and errors in flow rate by the occasional passage of liquid through the meter instead of gas. Adjusta-Cone® offers a flow range equivalent to 27 orifice plates, features automatic range changing and above all, is totally safe. Because Adjusta-Cone doesn’t use orifice plates it doesn’t cause any gas releases during the plate changing process. Adjusta-cone has been extensively analysed with computational fluid dynamics so is well suited to changing flow rates found in green hydrogen generation and in CO2 operations. We have developed unique sealing solutions for these gases to maximise accuracy and prevent leakage.

Integra-Cone for high pressure liquid and gas pumping applications

Integra-Cone™ is our first foray into high pressure gas measurement for offshore use. It was developed as an alternative to turbine meters which are often damaged by the rough service encountered during well servicing operations. Turbine meter users complained of losing the flow meter internals far too often, so we developed Integra-Cone as a viable alternative. With no moving parts, 689 bar (10,000 PSI) service and an integral transport frame, Integra-Cone is virtually indestructible bot in use and during set up.

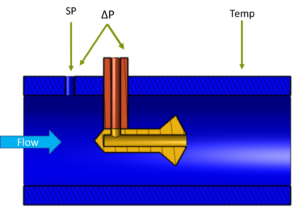

Hy-Cone™ HP – showing two x DP ports, 1 x Static pressure port, (1 x thermowell hidden)

Most recently, GM Flow have stepped into the hydrogen arena, with our latest development Hy-Cone™. This meter is also based on proven differential pressure cone meter technology and is designed for both low pressure electrolyser and high-pressure hydrogen fuelling applications. Hy-Cone™ LP is designed for low pressure (34.5 Bar) electrolyser applications, allowing users to continuously measure the flow rate of produced gas and monitor the efficiency of the electrolysis process. This meter has also been extensively tested and verified with computational fluid dynamics and physical flow testing at low pressures. The accuracy of the meter is around +/- 0.5% using advanced flow computers to continuously measure the pressure and temperature at the meter, then compute the flowing density, mass and volumetric flow rate of hydrogen passing through the device.

Differentia Pressure Cone Meter Operation

In vehicle fuelling applications, our high-pressure experience is expanded with Hy-Cone™ HP, with up to 1034 Bar operating pressures. Pressure testing this meter to 1550 Bar 22,500 PSI) guarantees and confirms our Finite Element Analysis of the body design. We plan to flow test this meter at 350 and 700 Bar operating pressure in the near future. Customers have commented that Hy-Cone looks very well designed and manufactured.

As with all our products, GM Flow offer a try before you buy approach, where your doubts can be alleviated and you can experience first-hand the service attitude that was developed and honed while serving demanding oil and gas customers.