As continuous growth, high competitive pressure and large production quantities in the manufacturing industry look set to continue, the entire processing chain, including manufacturers of packaging machines and checkweighers, is placed under greater performance pressure than ever before. Confronted with the demand for ever increasing precision and higher speeds for packaging – often with the expectations of reduced costs – machine manufacturers are faced with a challenge.

As continuous growth, high competitive pressure and large production quantities in the manufacturing industry look set to continue, the entire processing chain, including manufacturers of packaging machines and checkweighers, is placed under greater performance pressure than ever before. Confronted with the demand for ever increasing precision and higher speeds for packaging – often with the expectations of reduced costs – machine manufacturers are faced with a challenge.

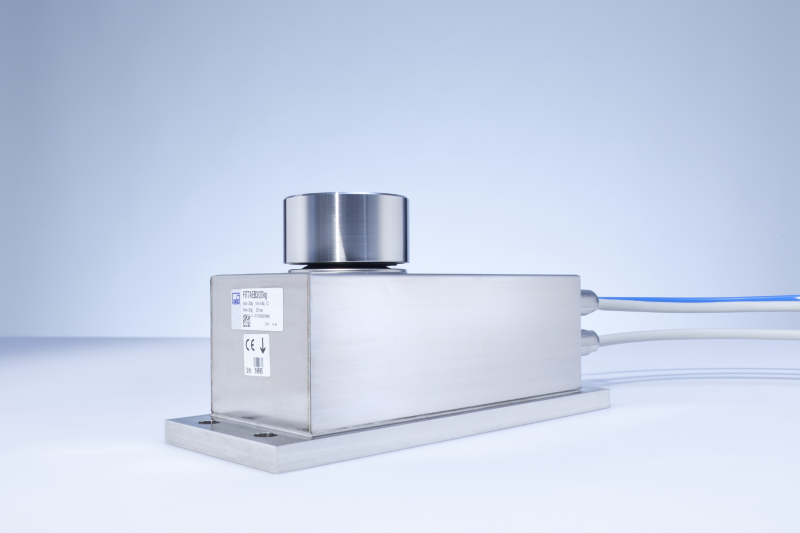

One of the most crucial components for constructing powerful packaging machines is the load cell. Offering an alternative to the traditional load cell which is based on the electromagnetic force compensation (EFC) principle, the latest range of digital load cells from HBM have been specifically designed to meet the needs of demanding requirements of weighing in modern manufacturing lines.

Precision and speed are the two determining criteria for load cells, ultimately because both factors save cost; precision because it makes for improved safety margins, and speed because faster weighing means greater output.

As dynamic movements and vibrations require sophisticated digital signal processing and calculation methods to determine the correct weight in a very short time, digital load cells also make it possible to achieve more than 180 weighing processes per minute, resulting in faster and ultimately, more productive packaging processes.

As dynamic movements and vibrations require sophisticated digital signal processing and calculation methods to determine the correct weight in a very short time, digital load cells also make it possible to achieve more than 180 weighing processes per minute, resulting in faster and ultimately, more productive packaging processes.

Extremely robust in comparison to traditional load cells, digital load cells are also less likely to be damaged and can be easily replaced. Featuring a smooth stainless steel surface, they can also be cleaned quickly and easily, which makes for short down times and correspondingly higher availability.

Another key factor to take into consideration is that, in order to achieve a productive weighing and packaging process, a smooth running production line is a necessity. The digital diagnostic channel can be used to analyse results during operation, predicting any potential errors or malfunctions and for this reason, digital solutions, with their wide range of possibilities, are in greater demand than ever before.

Suitable for use in a wide range of production environments, the FIT7A and FIT5A digital load cells from HBM are the perfect solution where speed and precision is a key consideration. Featuring a class C4 accuracy per OIML R60 and a maximum scale division Y of up to 25,000, the FIT7A addresses the problem of bottlenecks, which can slow down production rates. Dramatically increasing speed and reducing overall costs, sophisticated new technology, which is incorporated in to the innovative FIT7A also means that is now possible to perform an impressive 180 weighings per minute. And where harsh and ambient environments are an issue, the FIT5A from HBM features integrated overload protection and the suitability for legal-for-trade applications per OIML R60 up to 3,000 divisions, ensuring accuracy, reliability and overall safety in any heavy-duty production facility.

Suitable for use in a wide range of production environments, the FIT7A and FIT5A digital load cells from HBM are the perfect solution where speed and precision is a key consideration. Featuring a class C4 accuracy per OIML R60 and a maximum scale division Y of up to 25,000, the FIT7A addresses the problem of bottlenecks, which can slow down production rates. Dramatically increasing speed and reducing overall costs, sophisticated new technology, which is incorporated in to the innovative FIT7A also means that is now possible to perform an impressive 180 weighings per minute. And where harsh and ambient environments are an issue, the FIT5A from HBM features integrated overload protection and the suitability for legal-for-trade applications per OIML R60 up to 3,000 divisions, ensuring accuracy, reliability and overall safety in any heavy-duty production facility.

A look at today’s market shows that the advanced development of digital load cells makes an excellent alternative to load cells based on electromagnetic force compensation. Precise, durable and reliable, they deal masterfully with malfunctions and can be integrated seamlessly into most existing machine designs.

As machine manufactures are confronted with a demand for greater precision and higher speed, particularly in the food market, we can see how, whilst this may be a challenge for machine manufacturers, it is in fact an opportunity to get a firm footing in other growth markets, if they have the right response to the demand.

As machine manufactures are confronted with a demand for greater precision and higher speed, particularly in the food market, we can see how, whilst this may be a challenge for machine manufacturers, it is in fact an opportunity to get a firm footing in other growth markets, if they have the right response to the demand.

HBM will also be showcasing its latest series of load cells and models at this year’s PPMA Total Show on the 27th – 29th of September at NEC Birmingham, which also include its ‘Easy to Clean’ PW25 and the aseptic PW27 range of load cells, which have been developed to meet the strict hygiene regulations required in production.

Designed for use in filling systems and packaging plants, in multi-head combination weighers and static scales, the range is hermetically encapsulated and housed in stainless steel, making it compatible with all cleaning agents and disinfectant agents, which are commonly used in the production process. Featuring a clean and smooth cylindrical design that is non-absorbent and free from imperfection, such as grooves and gaps, to avoid gathering, the top surfaces of the load cells are also inclined to prevent the collection of dust, product residue or water droplets, reducing the possibility of contamination.

Ingress protected to IP68/IP69, the hygienic PW27 load cell, which enables efficient and accurate weighing equipment to be used in fields where aseptic production is required, has also been developed to meet the guidelines set out by the EHEDG (European Hygienic Engineering and Design group).

To illustrate its impressive test and measurement capabilities, HBM will be offering visitors the opportunity to view a filling machine model in action at this year’s PPMA Total Show 2016, alongside an eccentric press demonstration model, for measured values of force and displacement.

Also featuring a series of beam load cells and modules for use in all sectors where goods are produced, processed or controlled and a range of presentation boxes, visitors can visit HBM on Stand C86 to find out more about solutions for dynamic weighing processes.

For further information on the HBM range of digital load cells, contact HBM on +44 (0) 20 8515 6000 or via email: info@uk.hbm.co.uk or visit the HBM website at www.hbm.com/en/menu/seminars/seminar-calendar/

Founded in Germany in 1950, HBM is today the technology and market leader in the field of test and measurement. HBM’s product range comprises solutions for the entire measurement chain, from virtual to physical testing. The company has production facilities in Germany, USA and China and is represented in over 80 countries worldwide.