Keith J. Albert, from Artel, outlines the common sources of error in the automated liquid handling systems used in life science laboratories. He emphasises the importance of accuracy and precision in such environments, and suggests ways of reducing the risk of error

Keith J. Albert, from Artel, outlines the common sources of error in the automated liquid handling systems used in life science laboratories. He emphasises the importance of accuracy and precision in such environments, and suggests ways of reducing the risk of error

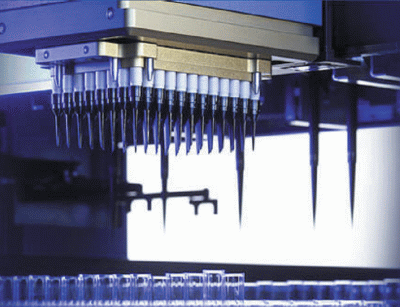

The use of automated liquid handling equipment to test and reproducibly screen thousands of compounds is essential in life science laboratories. Along with an increase in use of automated liquid handlers, transferred volumes are getting smaller, yet the accuracy of these transfers is increasingly important. Automated liquid handlers are generally used to increase the productivity and repeatability of volume transfers, but they can be prone to error.

If automated liquid handlers are not dispensing the desired amount of critical reagent(s), then an unseen error could increasingly propagate as a process continues. Even slight discrepancies in the amount of transferred reagent can compromise results, leading to poor quality, useless data and downstream costs associated with remedial actions. If the liquid handling systems are over-delivering target volumes of expensive and/or rare reagents, the loss of precious materials will be costly.

It is therefore important to understand how some errors can be recognised and avoided to maintain liquid handling quality assurance, especially when transferring critical reagents.

The following are common sources of error in automated liquid handling:

• Tip Types and Contamination

• Tip Types and Contamination

The types of tips employed on the liquid handler are critical to the accuracy and precision of each volume transfer. Some liquid handlers employ fixed, or permanent, tips, which avoid the recurring consumable cost required for disposable tips. When using fixed tips, however, there must be rigorous and effective tip washing protocols in place to avoid contamination and liquid handling error. It is recommended that tip washing methods have validation protocols to prove the efficiency of the washing steps.?This ensures tips are clean and the entire sample plug is removed.

When using disposable tips, the tip types are important to the integrity of the volume transfer. Vendor-approved tips, as opposed to the cheaper ‘bag of tips’ option, should always be employed. Tip performance has been found to be directly related to quality because tip material, shape, properties, fit and wet-ability are all important factors for repeatability. Cheaper, bulk tips might not fit properly on the liquid handler, which may result in variable wetting/delivery properties. In some cases, the liquid handlers may be incorrectly blamed for inconsistent performance when the tips are the root cause of error.

Another source of error that can occur when using automated equipment is contamination. Users should evaluate their systems and tips to ensure that residual droplets do not remain after a sample is transferred. Adding a trailing air gap following a reagent aspiration can minimise the chances of liquid slipping, or falling, out of the tip. Users should also plan when and where disposable tips are ejected, to ensure that contamination is not caused by random reagent splatter onto the deck workspace.

• Sequential Dispensing Inaccuracies

In some liquid handling protocols, a relatively large volume of reagent is aspirated and then sequentially, or systematically, dispensed across a microtiter plate. Users must ensure that, upon dispensing, the tips are not touching any liquid in the wells to avoid contamination or dilution. If an automation method employs a sequential transfer, users should validate that the same volume is dispensed in each successive transfer as it is common for the first and/or last dispense to transfer a slightly different volume.

• Serial Dilution Transfers

Automated liquid handlers are routinely employed to perform serial dilution protocols and users need to verify that that the volume transfer is accurate and that each well is efficiently mixed before the next transfer takes place. If the reagents are not accurately transferred and the wells are not well-mixed, the concentration of critical reagent will be different compared to the assumed theoretical concentration levels across the plate. The experimental results will be flawed and users may have no indication that inefficient mixing and/or transfer are to blame.

• Pipetting Methods and Method Parameters

One of the first steps in minimising error is to choose the right pipetting technique, such as forward-mode or reverse-mode pipetting. With forward mode, the entire aspirated reagent in the tip is discharged and is often used for most aqueous reagents. Reverse, or waste, mode is a pipetting technique where more reagent is aspirated into the tip than dispensed and is often used for viscous or foaming liquids.

To reduce liquid handling error, laboratories must implement regular calibration programs and verification checks for volume transfer accuracy. The evaluation method should be standardised, fast and easy to implement, and also minimise instrument downtime and required resources.

To maintain analytical integrity, it is recommended that a volume verification method of performance evaluation be continuously implemented to understand if critical volumes are being accurately and precisely transferred. As process control within a laboratory continues to be emphasised, a robust volume verification method should be implemented so that liquid handler behaviour is known, optimised, and verified to deliver the desired target volumes for all levels of assay development. The more frequently liquid handler checks are performed, the sooner malfunctioning liquid handlers will be detected, fixed and brought back on-line.