–The first controller to offer a unique choice of communications

and greater efficiency with Cascade Autotune —

Invensys Operations Management, a global provider of technology systems, software solutions and consulting services to the manufacturing and infrastructure operations industries, has introduced the latest version of its Eurotherm® nanodac™ recorder/controller, which in one short year has seen three innovative updates that include an optional Dual Channel Programmer with access to over 300 programs, better communications integration, and greater storage flexibility for longer local data archiving with ‘Store & Forward’ data retrieval and connectivity to the company’s Wonderware® Historian for easier restoration, reporting and analysis.

Invensys Operations Management, a global provider of technology systems, software solutions and consulting services to the manufacturing and infrastructure operations industries, has introduced the latest version of its Eurotherm® nanodac™ recorder/controller, which in one short year has seen three innovative updates that include an optional Dual Channel Programmer with access to over 300 programs, better communications integration, and greater storage flexibility for longer local data archiving with ‘Store & Forward’ data retrieval and connectivity to the company’s Wonderware® Historian for easier restoration, reporting and analysis.

At just 92 millimeters high and wide and 90 millimeters deep, the powerful nanodac recorder/controller combines unprecedented graphical recording capabilities with versatile control, communications, remote visualisation (via a webserver) and reporting to help customers achieve productivity excellence.

The Eurotherm product brand, from Invensys, is renowned for the quality of its measurement circuitry. The kind of accuracy achieved by their products ensures that any errors are kept to a minimum and provides much closer tolerances to aid quality measurements and control stability.

The Eurotherm product brand, from Invensys, is renowned for the quality of its measurement circuitry. The kind of accuracy achieved by their products ensures that any errors are kept to a minimum and provides much closer tolerances to aid quality measurements and control stability.

The Eurotherm nanodac device has an intuitive easy to use screen with clear trend visualization in both live and historical modes. It has a choice of operator friendly displays including vertical and horizontal trends, numerical and bar graph runtime views and a text message display

Communications is a significant requirement within industrial processes and as you might expect the Eurotherm nanodac controller/recorder lives up to expectations, allowing you to bundle your communications with one direct connection utilizing Ethernet protocols such as Modbus TCP/IP MasterSlave for better integration with your PLC and/or Eurotherm or third party instrumentation

Communications is a significant requirement within industrial processes and as you might expect the Eurotherm nanodac controller/recorder lives up to expectations, allowing you to bundle your communications with one direct connection utilizing Ethernet protocols such as Modbus TCP/IP MasterSlave for better integration with your PLC and/or Eurotherm or third party instrumentation

The optional Dual Channel Programmer allows the operator to vary the setpoint with ease, with access to 300 separate programs.

Another new innovation gives greater efficiency for slow moving processes, with the new Advanced Cascade Control Block. Cascade control is an ideal solution for processes such as

• Heat treatment furnaces

• Vacuum furnaces

• Autoclaves

• Semiconductor diffusion

• Batch reaction vessels

• Heat exchangers

• Crystal growth

• Distillation columns

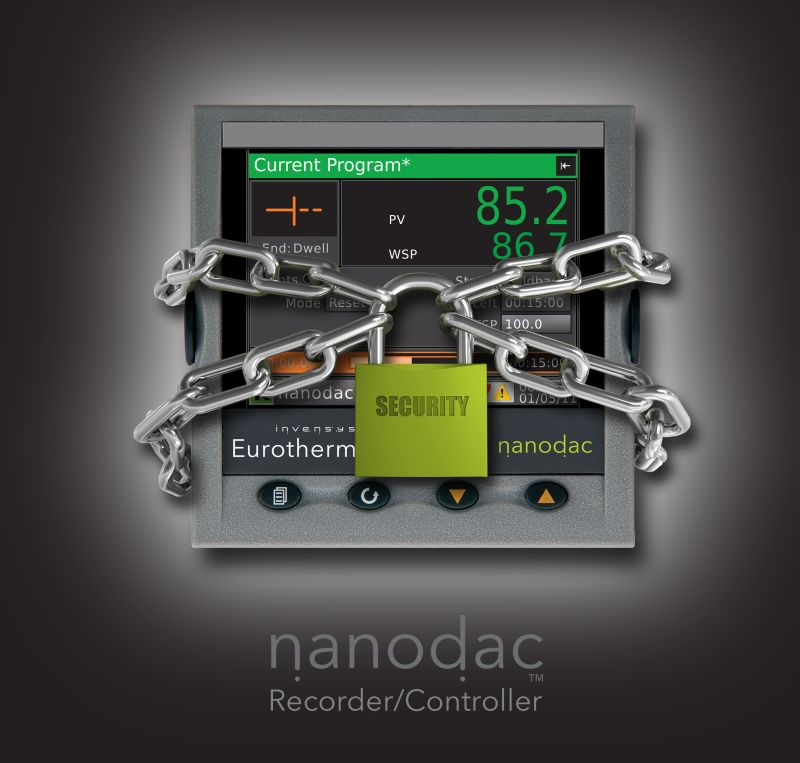

Invensys Eurotherm has also added OEM security which prevents unauthorised personnel from copying client configurations. Protecting our customers’ solutions and intellectual property is something that we take very seriously and hence this security function provides peace of mind. Other benefits include an optional wash down front which is ideal for sanitary applications.

“High-integrity data collection and retention for continuous or batch processing is critical for many industries,” said Bob Postlethwaite, global marketing director, Invensys Operations Management. “Without a local collection and retention device, when communications fail, processors risk losing important data. For a food and beverage or pharmaceutical manufacturer, for example, that could lead to a batch being quarantined or even scrapped. With its local historian and powerful memory, the Eurotherm nanodac recorder/controller can store up to 34 set-up values, and the ‘Store & Forward’ connection to our Wonderware Historian component ensures that data retrieval is automatically implemented whenever needed.”

In addition to its extensive data acquisition capability, the Eurotherm nanodac instrument also has an option to provide two high stability PID loops. The many advantages of this include 2 off dual output loops for direct/reverse or heat/cool applications, the unique Eurotherm PID algorithm, and the unique Eurotherm Autotune facility that actually works.

Both the product itself and its remote configuration software support several languages, including English, French, German, Italian and Spanish. As standard the device also:

- Meets many exacting standards for measurement, including Nadcap for Aerospace compliance and it can also be used to aid 21CFR Part11 compliance for Pharmaceutical Electronic Records.

- Has up to eight universal inputs coupled with high-density recording and dual PID control loops, making it both affordable and cost effective.

- Produces tamper-resistant files that can be retained in a long-term archive

With 50 megabytes of flash memory for data storage, as well as an on-screen help system, the device allows plant-floor operators and supervisors to monitor and discuss the health of their process from virtually anywhere, creating a fully empowered workforce that can use real-time operating information to make better operating and business decisions.

With such a skill set the nanodac recorder/controller is suitable across a wide range of applications:

Extrusion

- Injection moulding

- Hot Runners

- Chillers

Food & Beverage

- Pasteurisation

- CIP / SIP

- Cookers / Sterilisers

Healthcare/Pharma

- Sterilisers (Industrial Pharma & Hospitals)

- Small Autoclaves

- Refrigeration (Blood/Drugs)

- Blood Cell Incubation

- CIP / SIP

General Application

- Bench Mount Ovens

- Pottery Kilns

- Baking – Bread, Pizza, etc.

- Environmental Chambers

The Eurotherm nanodac recorder/controller is available now

For more information about the nanodac recorder/controller, please visit www.eurotherm.com/products/controllers/nanodac.