While analytical measurements are necessary in many industries for environmental compliance, safety or process monitoring, one chemical manufacturer has found an added benefit in using Endress+Hauser’s Memosens digital sensors – significantly increased profits!

While analytical measurements are necessary in many industries for environmental compliance, safety or process monitoring, one chemical manufacturer has found an added benefit in using Endress+Hauser’s Memosens digital sensors – significantly increased profits!

Shepherd Widnes Ltd is part of the Shepherd Chemical Company, one of the world’s foremost producers of speciality metal-based products. From its manufacturing site in Widnes the company has been producing cobalt, manganese and nickel salts for over 30 years. Its products are used widely in many products, including as a supplement to animal feed and as pigment in paint and glazing products.

In order to manufacture inorganic salts to the required purity and morphology, the chemical processes that the raw materials pass through must be closely monitored, controlled and optimised. The Shepherd Widnes team, had found it a challenge to do this consistently. In the past, they relied on visual assessment of some processes, where each step of the extraction could be monitored by observation of an obvious colour change. While this allowed them to confirm that the extraction process was working, it didn’t present an opportunity for optimisation and as a result, product quality was inconsistent. Consequently some batches needed to be supplemented by blending with additional, high purity metal salts, which would reduce the profit level for that batch.

In order to manufacture inorganic salts to the required purity and morphology, the chemical processes that the raw materials pass through must be closely monitored, controlled and optimised. The Shepherd Widnes team, had found it a challenge to do this consistently. In the past, they relied on visual assessment of some processes, where each step of the extraction could be monitored by observation of an obvious colour change. While this allowed them to confirm that the extraction process was working, it didn’t present an opportunity for optimisation and as a result, product quality was inconsistent. Consequently some batches needed to be supplemented by blending with additional, high purity metal salts, which would reduce the profit level for that batch.

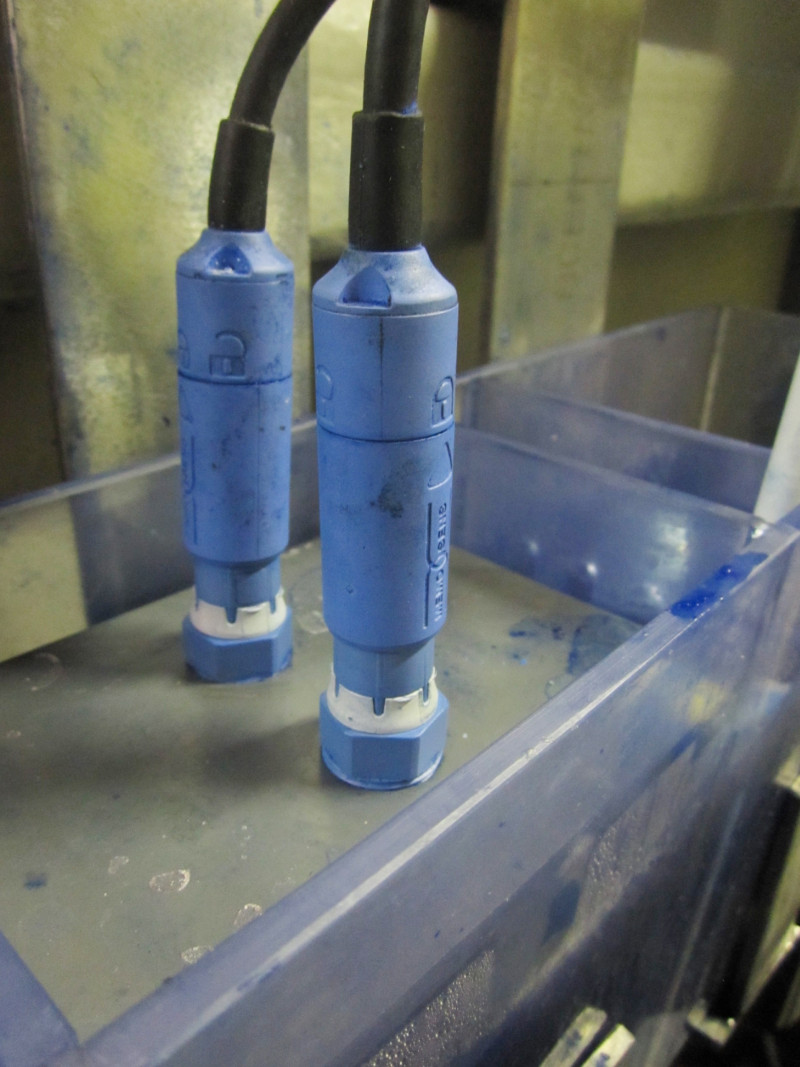

At the start of 2010, Shepherd Widnes began looking at ways of optimising their processes. pH is key as each metal impurity has an optimum pH at which it precipitates from the solution. By monitoring and adjusting the pH at each stage of the process, maximum impurity extraction can be ensured. The problem is that most pH measuring instruments are too delicate to cope with the humidity and physical conditions found on this site. Various systems were trialled but only when the Endress+Hauser Memosens non contact digital sensors were installed was the required level of measurement and control achieved.

Working closely with the Endress+Hauser analytical team, Memosens dual validation pH monitoring systems were put in place. Each installation consists of the new Liquiline CM442 dual input transmitter and two CPS71D electrodes. Perspex assemblies with a weir and baffle plate were used to produce a steady, uniform flow rate and stable measurement. A further, single channel device was mounted in the laboratory.

Endress+Hauser’s Memosens system has proved to be robust enough to cope with the difficult on-site conditions, while reducing costs and maximising product quality and process efficiency. Measurements which previously could not be made using analogue pH systems were made possible using the contactless, inductive Memosens technology. Furthermore, with several pH systems across the site, the frequent need for calibration and replacement of analogue electrodes and cables was both time consuming and costly. Use of the Memosens sensors with a Liquiline device mounted in the laboratory allows electrodes to be cleaned, maintained and calibrated offline. Pre-calibrated sensors can be simply swapped in with minimal process downtime. Furthermore, Endress+Hauser worked with the Shepherd Widnes team to ensure they had an appropriate maintenance schedule and that operatives were trained to correctly maintain the equipment. Engineers are able to interrogate the sensor to monitor operating hours and conditions, to establish the date of the last calibration and monitor changes in slope, which provides an indication of the sensor’s health. This allows for effective predictive maintenance. What’s more, the ability to perform maintenance procedures under laboratory conditions also serves to increase sensor lifetime. As a result, none of the sensors or cables had failed in over six months from the initial installation, which represented a big cost saving.

The Shepherd Widnes team is delighted with the solution and the Memocheck simulation tool is also now used to perform simulation of pH and temperature values on the transmitter. This enables quick and easy verification of the complete measuring chain for optimum process safety.

The installation of the Memosens system has had a major contribution to the control of the extraction process. “The pH control system has led to 10 fold reduction in losses and a consistent product quality. We couldn’t be happier.” reports Paul Croft, Site Manager.

Web: www.uk.endress.com

Web: www.uk.endress.com

Email: info@uk.endress.com

Tel: 0161 286 5000