Cros’frais and Arômatt are sister companies, selecting, processing and packaging some of France’s most popular brand of premium and mid-range to economy olive products respectively. With both companies seeking to increase production capability, Ishida France was tasked with installing a weighing system that could handle all types of olives and deliver accurate weighments at speed to a thermoformer.

Cros’frais and Arômatt are sister companies, selecting, processing and packaging some of France’s most popular brand of premium and mid-range to economy olive products respectively. With both companies seeking to increase production capability, Ishida France was tasked with installing a weighing system that could handle all types of olives and deliver accurate weighments at speed to a thermoformer.

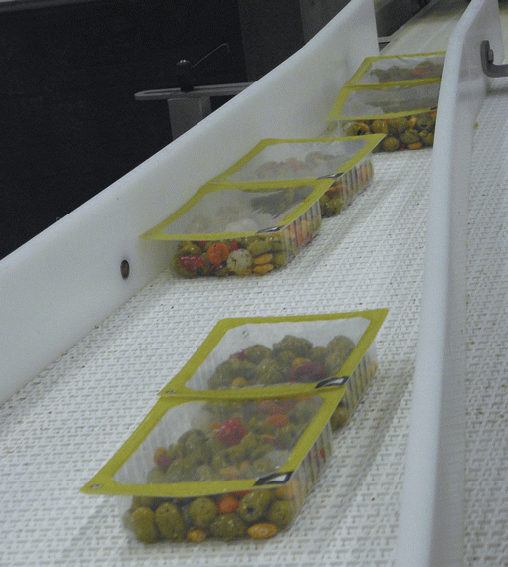

The selected ten-head Ishida RS Series model features larger 3l hoppers, and incorporates combination calculation software that makes more weight combinations available during each weigh cycle, so the weigher will seldom, if ever, need to select a weight outside the specified range. This helps to guarantee, within small margins, the same weight of product in each pack.

Once the product has been delivered to the weigher, it is moved along by the Ishida AFD vibratory feeder system. Alerted by a loadcell sensor under the dispersion table, the system automatically adjusts its level of vibration to suit the product flow, reducing the need for operator intervention, however oily or sticky the product might be. Ishida has also installed a distribution system beneath the weigher to deliver the weighments into the thermoformer.

Factory manager Stéphane Varlet says that 120g trays of olives are produced ‘with the very precise weight of plus or minus 0.1g.’ meaning giveaway is practically eliminated.

Ishida

T: 0121 607 7700