Ensuring the production process meets current hygienic, food safe or Atex regulations can be one of the main challenges facing any production facility.

Ensuring the production process meets current hygienic, food safe or Atex regulations can be one of the main challenges facing any production facility.

When the budget is simply not there to have a fully automated production system, handling different products in a safe, consistent manner can prove quite difficult.

Often the default position can be to incorporate a manual handling system utilising either existing or additional personnel, but can a North Ridge pump kit be the solution to this?

How a 50 year old bakery upgraded production with a North Ridge Pump Kit

A traditional family run bakery established for over 50 years required a fully hygienic, easy to clean mobile pump to transfer Fruit Jams, Toffee Sauce, Fruit curds and Whipped cream. The variety of products posed a real challenge to ensure components did not wear prematurely, that damage could not be easily performed to the pump and that the customer had a low maintenance solution.

Viscous high temperature sticky liquids

Some of the products are directly dispensed from a cooking kettle into the pump at an average temperature of 100 – 110 °C whilst others were incredibly viscous as they were stored in a fridge before being used.

The customer needed a bespoke multipurpose solution for their processes, which was sanitary grade, capable of handling all the products in question, suitable for high viscosities and temperatures up to 120 °C. It also had to have a very gentle pumping action due to the shear sensitivity of the whipped cream.

High temperature liquids can have a negative impact on seals, NPSH and the overall pump lifespan so careful consideration must be taken during pump selection.

Current Manual Handling Process

Current Manual Handling Process

Their current procedure involved manually transferring sauces via totes and buckets, however the customer wanted to improve their process to automate food transfer, reduce the likelihood of burns or accidents, and eliminate manual lifting and tipping of containers.

They needed a custom cost-effective unit that operates similar to a semi-automatic liquid filling machine.

Our Easy to use, low maintenance, automated mobile solution

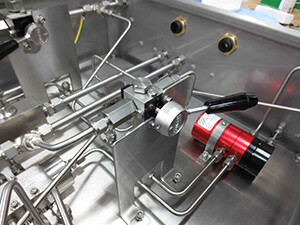

We supplied a completely bespoke pump system consisting of one DX hygienic progressing cavity pump, mounted on a mobile trolley, with an integrated control panel.

The pump is 3A sanitary certified, which means it is suitable for CIP (cleaning-in-place) and SIP (sterilization-in-place) furthermore, is specifically designed without dead zones or areas where product can build up ensuring the internal components are fully clean after operation and guaranteeing zero cross contamination when handling different liquids.

We also ensured the exterior of the unit was easy to clean by fitting a stainless-steel shroud that covers both the motor and the gearbox.

Besides having an integrated inverter, the control panel has several other safety and operation features, such as start/stop switch, reverse (clockwise/anti-clockwise) switch, emergency stop, alarm for motor overload protection and temperature control sensor, with alarm to prevent damage (dry running protection).

There is also the added feature of controlling the inverter via the panel or by the use of an App through Bluetooth where operators can also view the status of the pump. This feature is extremely beneficial for the customer as the pump has to operate at a slow speed when handling whipped cream.

We are proud to say that thanks to our pump kit the customer improved their production efficiency dramatically, which in the food industry translates as an increase in profitability. The layout enabled users to operate the unit with very little training due to the simplicity of design but also built-in protection ensures the unit cannot be damaged easily.

We are proud to say that thanks to our pump kit the customer improved their production efficiency dramatically, which in the food industry translates as an increase in profitability. The layout enabled users to operate the unit with very little training due to the simplicity of design but also built-in protection ensures the unit cannot be damaged easily.

Repeatable Outcomes, across multiple processes without loss of flow

North Ridge pump kits have been specifically designed to handle a range of fluids from thin oils and water like substances to viscous oil, sludge, creams and sauces across a broad range of temperatures without compromise to performance .

Units can be designed to be portable, and integrated with a control panel enabling units to not only be plug play, but also easy to use, without risk of accidental damage.

Future Proof Modular Design

Providing we understand your current and possible future requirements, kits can be constructed to be modular in design enabling them to be added to enabling them to change inline with your process.

If you have a manual handling process you are looking to improve, contact us or visit www.northridgepumps.com to see how we can help.

01773 302 660