Making the shift from preventative to predictive maintenance in emissions monitoring

- ABB launches Datalyzer, a new analyzer fleet monitoring application that transforms data into business value and improves plant and asset uptime.

- The new solution pre-empts major failure and reduces the risk of non-compliance, improving asset integrity and process safety.

- Out-of-the-box actionable insights and analytical applications combined with self-service analytics help close the skills gap.

Increased governmental and societal focus on emissions mean that industry is under ever greater pressure to increase the agility and reliability of emissions monitoring in real-time. ABB’s Datalyzer is designed to help customers respond to this challenge. The comprehensive, cloud-based modular application provides real-time analyzer status right across a fleet of analyzers and plants. In doing so, it lowers ownership cost and reduces capital expenditure.

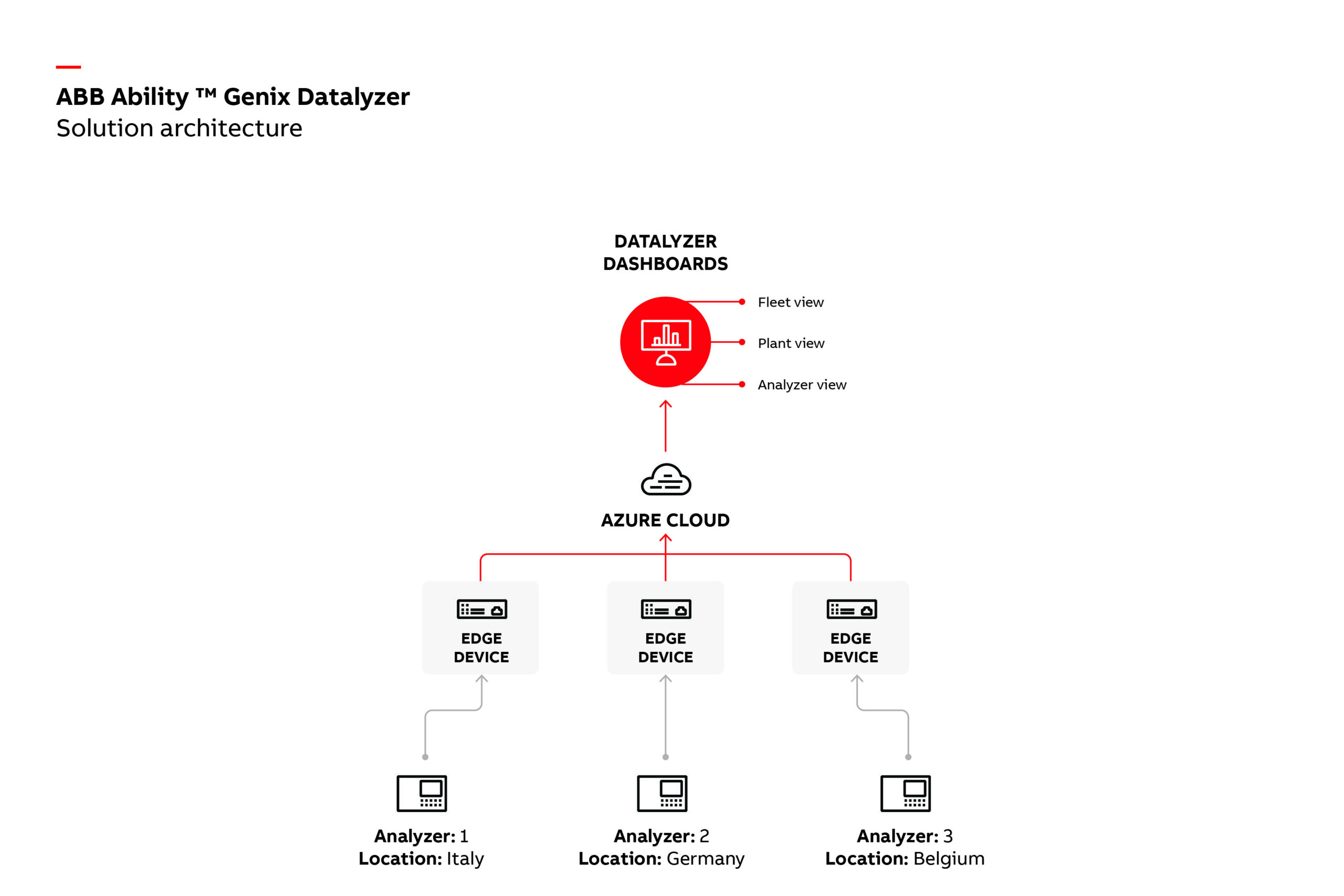

Real-time fleet status is realized by Datalyzer through the collection of data from emissions monitoring analyzers which is then routed to an on-site Edge device (Micro PC). The Edge device sends the relevant information up to Datalyzer which sits in the Microsoft Azure cloud. The application analyzes the data received transforming it into actionable insights.

The end user receives the information from Datalyzer across three different dashboard views. The first shows the Fleet view, the second the plant view and the third a more detailed analyzer view. This combination provides both an ‘at a glance’ vision of the overall analyzer status alongside valuable detailed asset parameters. Heatmaps of the installed base, historical trends and systems diagnostics are amongst the key parameters provided.

Datalyzer also offers QAL-3 assessment* and reporting and event-based notifications by e-mail. Live analyzer process data together with value added insights and reports are amongst the application’s key features. Historical trends are tracked for up to five years, providing the platform for predictive maintenance. Adherence to cyber security standards prevent unauthorized access while ensuring data integrity.

Datalyzer has been developed for industries that carry out continuous emissions monitoring such as power plants, the cement and metals industry and waste-to-energy plants. Continuous gas analyzers such as ABB’s ACF5000 and ACF-NT analyzers are compatible with the Datalyzer with extensions planned to include Advanced Optima and Easy Line in the first quarter of 2022.

Datalyzer forms a part of the suite of applications offered by ABB through the recently launched ABB Ability™ Genix™ Platform. The platform applies data analytics and industrial AI in order to provide next generation operational intelligence and insight.