The melting point of a substance is the point at which the solid phase converts to a liquid phase at 1 atmosphere of pressure. The melting point is usually recorded as a range, with the lower temperature the point at which liquid is first visible in the sample and the upper temperature when the last solid has completely melted. A pure crystalline substance normally melts at a specific temperature with a variance of around two degrees or less, however; substances that are not pure have melting points that are wider and lower than that of the published value principal component due to defects in the structure and a weakening of intermolecular bonds. During a melt the sample is heated up, with its’ particles absorbing the heat energy and turning it into kinetic energy, which causes them to vibrate and eventually overcome the attractive forces that are holding them together in a solid form. It is at this stage that a liquid can form.

The melting point of a substance is the point at which the solid phase converts to a liquid phase at 1 atmosphere of pressure. The melting point is usually recorded as a range, with the lower temperature the point at which liquid is first visible in the sample and the upper temperature when the last solid has completely melted. A pure crystalline substance normally melts at a specific temperature with a variance of around two degrees or less, however; substances that are not pure have melting points that are wider and lower than that of the published value principal component due to defects in the structure and a weakening of intermolecular bonds. During a melt the sample is heated up, with its’ particles absorbing the heat energy and turning it into kinetic energy, which causes them to vibrate and eventually overcome the attractive forces that are holding them together in a solid form. It is at this stage that a liquid can form.

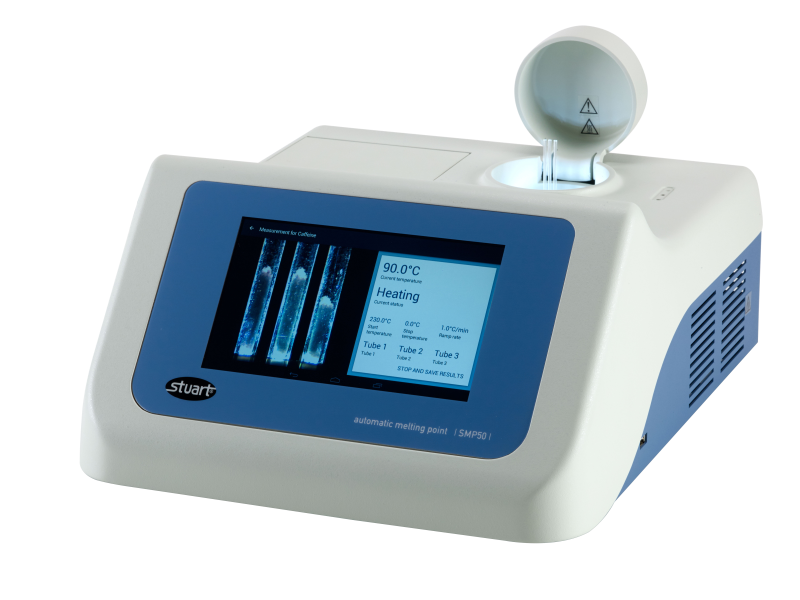

Melting Point Apparatus are used to determine sample melt, and are used for applications in pharmaceutical labs, quality control, academia, chemistry and industrial labs, particularly for the purity checking of raw materials received and compounds produced. They are often used to determine the temperature of the melting point of a substance. It is usual to carry out a melting point determination and check for consistency with at least a further two tests. These tests are undertaken in capillary tubes. The Stuart® SMP50 Automatic Digital Melting Point Apparatus can analyse three samples simultaneously, which can be captured and displayed as a video image of the melt on a large 7” touchscreen display, either straight away or at a more convenient time. On speaking to Renaud Foret, Category Manager, he explained some of the key attributes of this device “The SMP50, conforms to US Pharmacopeia (USP) and GLP requirements, and can accurately identify the melting point with its’ advanced digital image processing capability. If you are unsure of the melt temperature, use the rapid ramp mode to take a fast scan of the full temperature range. Set-up is easy and intuitive due to the Android™ menu system. You can take measurements, view results, save programs, set up user sign-ins, and download time-stamped videos and reports to a USB flash drive. Furthermore, there is a storage compartment for unused capillaries, which includes a glass cutter to open capillaries that are closed on both ends, and an area to hold three prepared sample capillaries safely away from the heat source.”

When using the Stuart® SMP50 Automatic Digital Melting Point Apparatus it is important to prepare samples correctly. For accurate melting point determinations, the sample should be dry. This can be achieved by placing the sample into a vacuum desiccator with desiccant overnight. The dry sample can then be placed onto a watch glass and grinded down into a fine powder with a glass rod. This is important as coarse, crystalline samples will give uneven heat transfer through the sample. The powdered sample should then be gathered into a small pile. The open end of the capillary can then be pressed into the sample to a depth of around 2mm. The glass capillary will need to be sealed at one end; if the capillary is open at both ends, seal one of the ends using a Bunsen burner. After the capillary tube has taken up the sample it should be inverted and tapped gently to pack the sample down in the sealed end. The process of filling is repeated as necessary until the final height of the sample is between 2-4mm. For accurate melting point determinations, it is recommended that three samples of the same material are prepared in the same way and analysed at the same time. The average of the results from the three capillaries can then be reported as the melting point of the sample. During this whole process it is important to: ensure that there is no sample on the outside of the tube before inserting it into the melting point apparatus; use a sample only once as some substances chemically decompose on heating; heat the sample slowly at 1-2ºC/minute; and perform a rapid melt with a ramp of up to 20ºC/minute if the melting point is unknown. Once the approximate melting point is known, a more appropriate plateau can be set, and a slower ramp rate used.

The Stuart® SMP50 Automatic Digital Melting Point Apparatus is our flagship product for this application, however other Melting Point Apparatus are available to suit requirements. If you have any queries please contact Stuart Category Manager, Renaud Foret for further details, renaud.foret@coleparmer.com.

Author:

Dr Julia Lock, Content Marketing Specialist

+44 (0)1480 274631

Julia.Lock@coleparmer.com