Torqueflow –Sydex have now become one of the UK’s leading suppliers of fluid handling equipment, especially well known for the supply of progressing cavity pumps from their sister company, Sydex in Italy. Employing this existing expertise we have partnered with another Italian manufacturer to extend our range and bring to the UK market an exciting series of digital mini & micro pumps.

Torqueflow –Sydex have now become one of the UK’s leading suppliers of fluid handling equipment, especially well known for the supply of progressing cavity pumps from their sister company, Sydex in Italy. Employing this existing expertise we have partnered with another Italian manufacturer to extend our range and bring to the UK market an exciting series of digital mini & micro pumps.

Infiniti was founded in 2006, born out of many years experience and the previous success of a well-established Italian metering machine company. This specialist division is dedicated to the research, development and manufacture of advanced dosing pumps and integrated systems with exceptional levels of dosing accuracy. The production plant is located near Fossano in Northwest Italy, where a committed technical team strives to design, source and supply the very best in both mechanical and electronic components based on considerable experience and an in-depth knowledge of manufacturing.

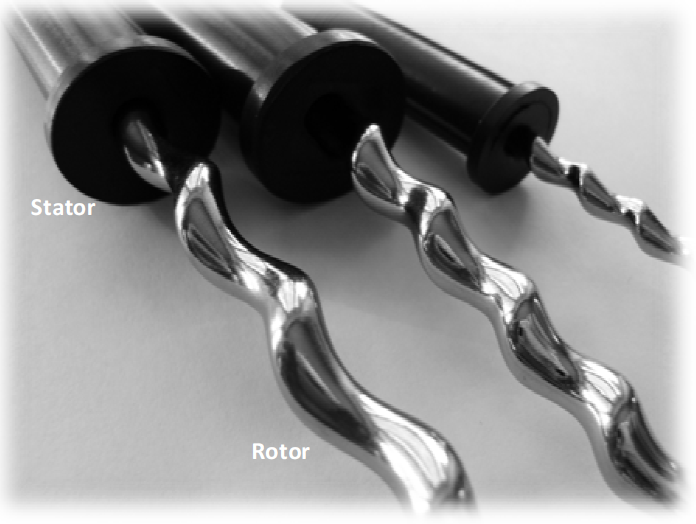

Infiniti® pump technology is based on the established and reliable progressing cavity concept. The rotating element “Rotor” and static counter-part “Stator” form an optimal chamber “Cavity”. Both rotor and stator are in contact over their entire length to create a continuous seal that prevents backflow ( slip ) even with high back pressure. The rotation of the rotor in the stator allows the fluid to be gently pushed to the next chamber without shearing or squeezing . A characteristic that enables the dosing of abrasive fluids as well as more viscous pastes. As the cavity along the seal line is always open, particles can also be handled without difficulty.

Infiniti® pump technology is based on the established and reliable progressing cavity concept. The rotating element “Rotor” and static counter-part “Stator” form an optimal chamber “Cavity”. Both rotor and stator are in contact over their entire length to create a continuous seal that prevents backflow ( slip ) even with high back pressure. The rotation of the rotor in the stator allows the fluid to be gently pushed to the next chamber without shearing or squeezing . A characteristic that enables the dosing of abrasive fluids as well as more viscous pastes. As the cavity along the seal line is always open, particles can also be handled without difficulty.

Rotors are hardened, giving lower wear rates and extended life. The exclusive Fini-Coat, an ENP coating techniques ensure they resist many corrosive chemicals and provide full FDA, USDA and NSF standards of conformity. Stators have been developed to minimise friction by using a special teflonised Viton® elastomer as standard; of course other materials are also available.

Rotors are hardened, giving lower wear rates and extended life. The exclusive Fini-Coat, an ENP coating techniques ensure they resist many corrosive chemicals and provide full FDA, USDA and NSF standards of conformity. Stators have been developed to minimise friction by using a special teflonised Viton® elastomer as standard; of course other materials are also available.

Quality control is extremely rigorous and the testing is performed on individual parts as well as the final assembly. Built to exacting standards they achieve a degree of functionality which ensures extreme reliability, the highest accuracy and utmost repeatability, even for those products normally considered to be difficult to process.

There are many recognised advantages & benefits of the pc design, not least the level of control and accuracy coupled with the simplicity, no extra valves needed, of operation.

The range comprises the Infiniti® Essential series, these standard dispensers can be used to dose a large variety of fluids and pastes: (conductive) epoxies, glass bead filled pastes, adhesives, sealants, optical fluids, soldering fluids and pastes. The Infiniti®Solution series have been developed for special OEM applications. Bespoke designs, built to individual or process discreet requirements are available within our Infiniti® NDA series (non-disclosed series). And just added: the ultra high accuracy, aCCura models.

The Essential series have been developed based on Infiniti’s long term experience within different market segments. These are easy to install, service and maintain & are readily available in standard or light duty versions.

PDM 17: Dosing volume 0.0015 to 0.075 lt. /min. (max. 4.5 lt./hr), per revolution = 0.15 cc with the Smallest possible shot = 0.0075 cc

PDM 70: Dosing volume 0.007 to 0.35 lt./min. (max. 21 lt./hr) , per revolution = 0.70 cc with the Smallest possible shot = 0.035 cc

PDM 80: Dosing volume 0.012 to 0.60 lt./min. ( max. 36 lt./hr), per revolution = 1.20 cc with the Smallest possible shot = 0.06 cc

Infiniti® Solution series have been developed to meet special machine requirements within dedicated market segments, offering additional features & benefits according to customer and application demands. Moreover , working with OEM’s and large volume users Infiniti® is able to tailor products specifically for any new applications from within the Solution and NDA series. A team of electronics and pump design specialists are available to work with the customer’s own team to achieve an optimal solution.

The Infiniti®aCCura series share an outstanding level of accuracy, ± 1% or = 99% of volume with a 99% repeatability

aCCura-Doser 1 – Dosing volume 0,16 to 20,0 cc/min, per revolution = 0,16 cc, Smallest shot = 0,010 cc (10 µl)*

aCCura-Doser 2 – Dosing volume 0,03 to 3,75 cc/min, per revolution = 0,03 cc, Smallest shot = 0,004 cc (4 µl)*

Pump Manager software

The Infiniti “Pump Manager software” can control all Essential, Solution & aCCura series pumps from within a Microsoft Windows® environment. The standard “Single Pump Manager“ package has been developed to handle almost all dosing applications. The operation is easy and the software requires little system overhead or storage capacity. Different screens show where you can program the velocity and the dosing volume. The software is extremely simple to understand and easy to use. Particularly relevant is the controlled “suckback” feature that prevents dripping wastage and inaccuracy.

02380 007 999